As a populous country, India’s achievements in the recycling field have attracted much attention. Recently, our factory welcomed a group of Indian delegations to visit. Their main purpose was to gain an in-depth understanding of the Lead Cupola Furnace we designed and produced, which plays an indispensable role in the lead-acid battery recycling industry. Our professional technical staff provide a full range of services to Indian customers, allowing them to have a deeper understanding of our technical products.

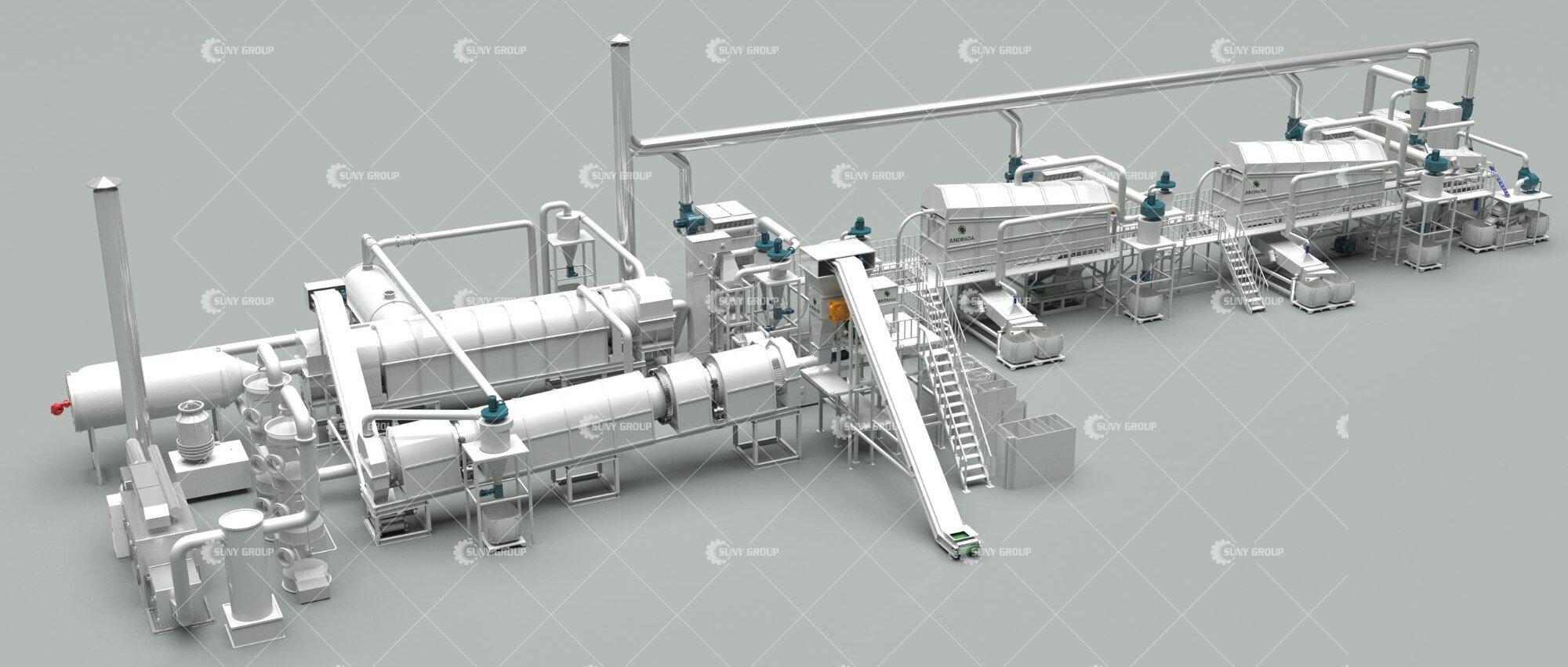

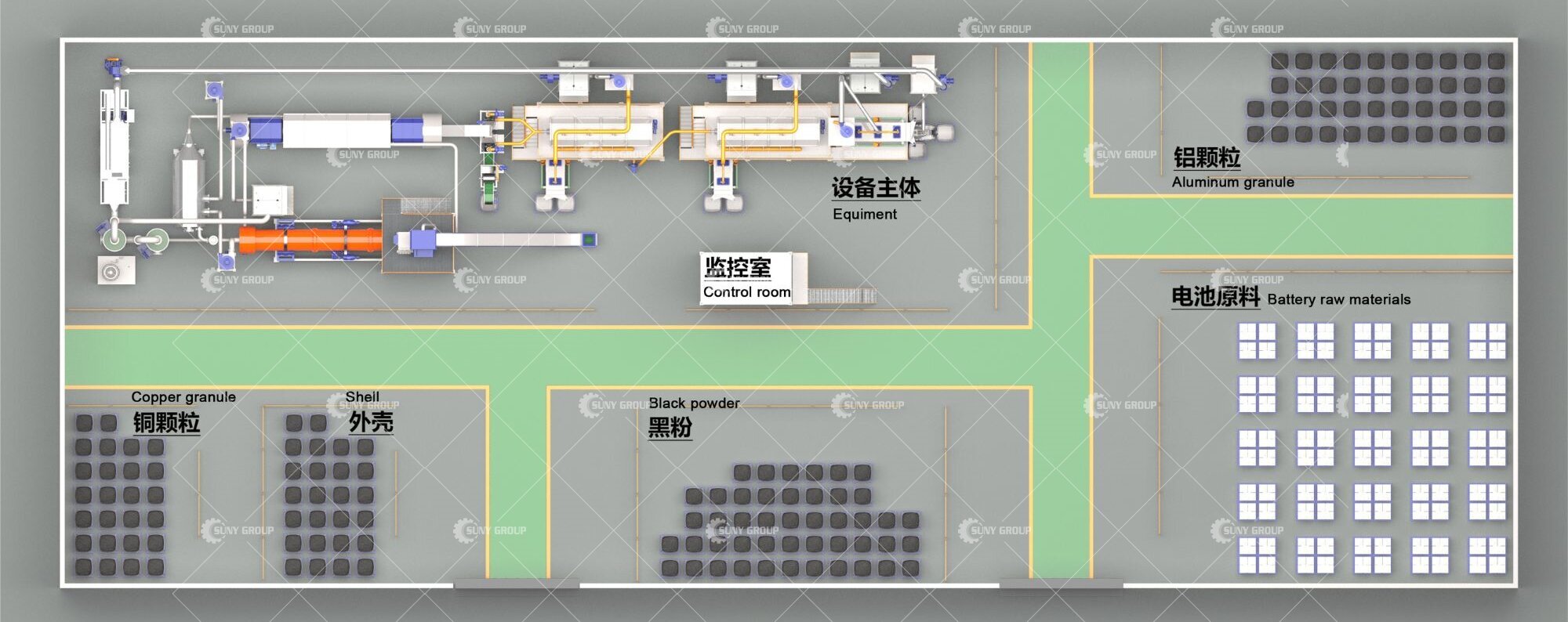

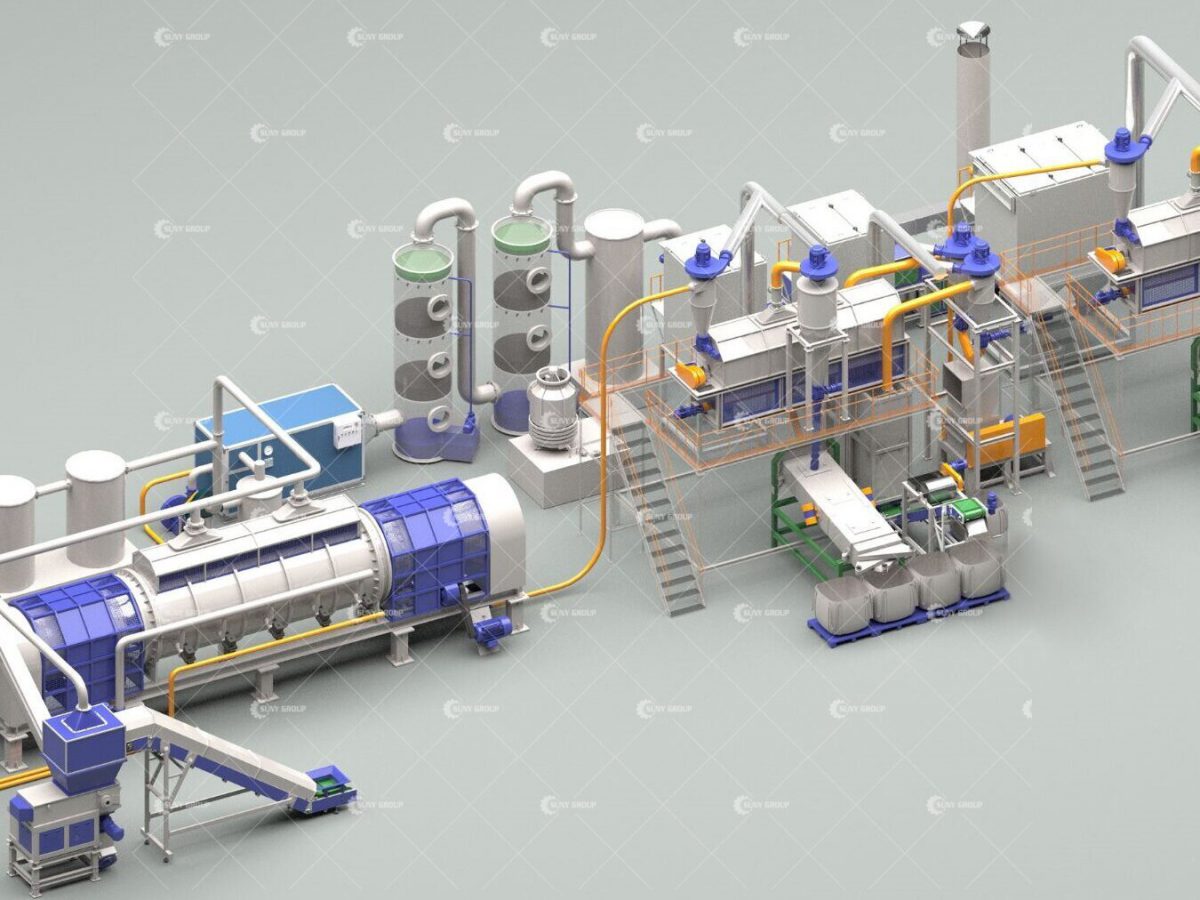

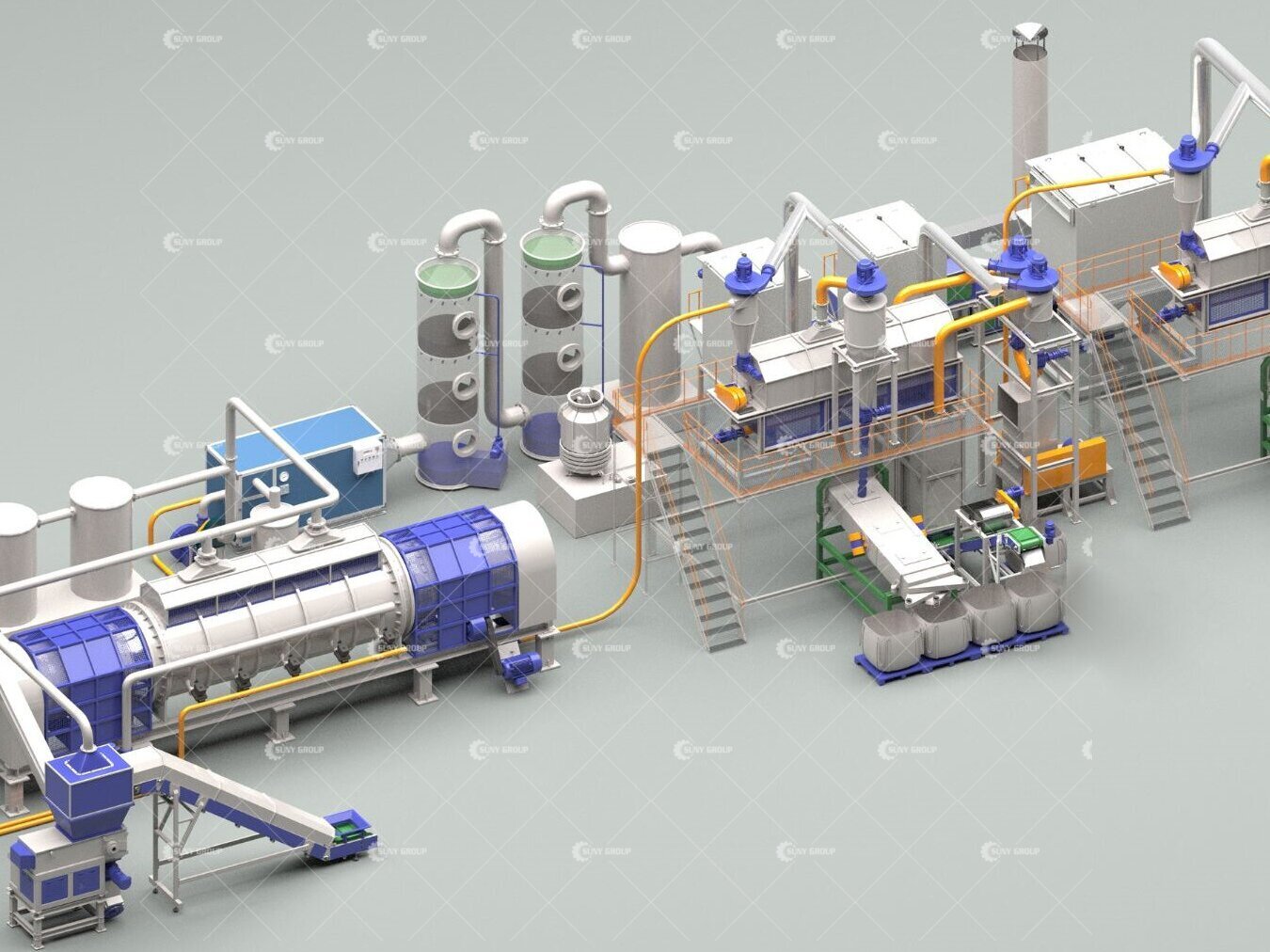

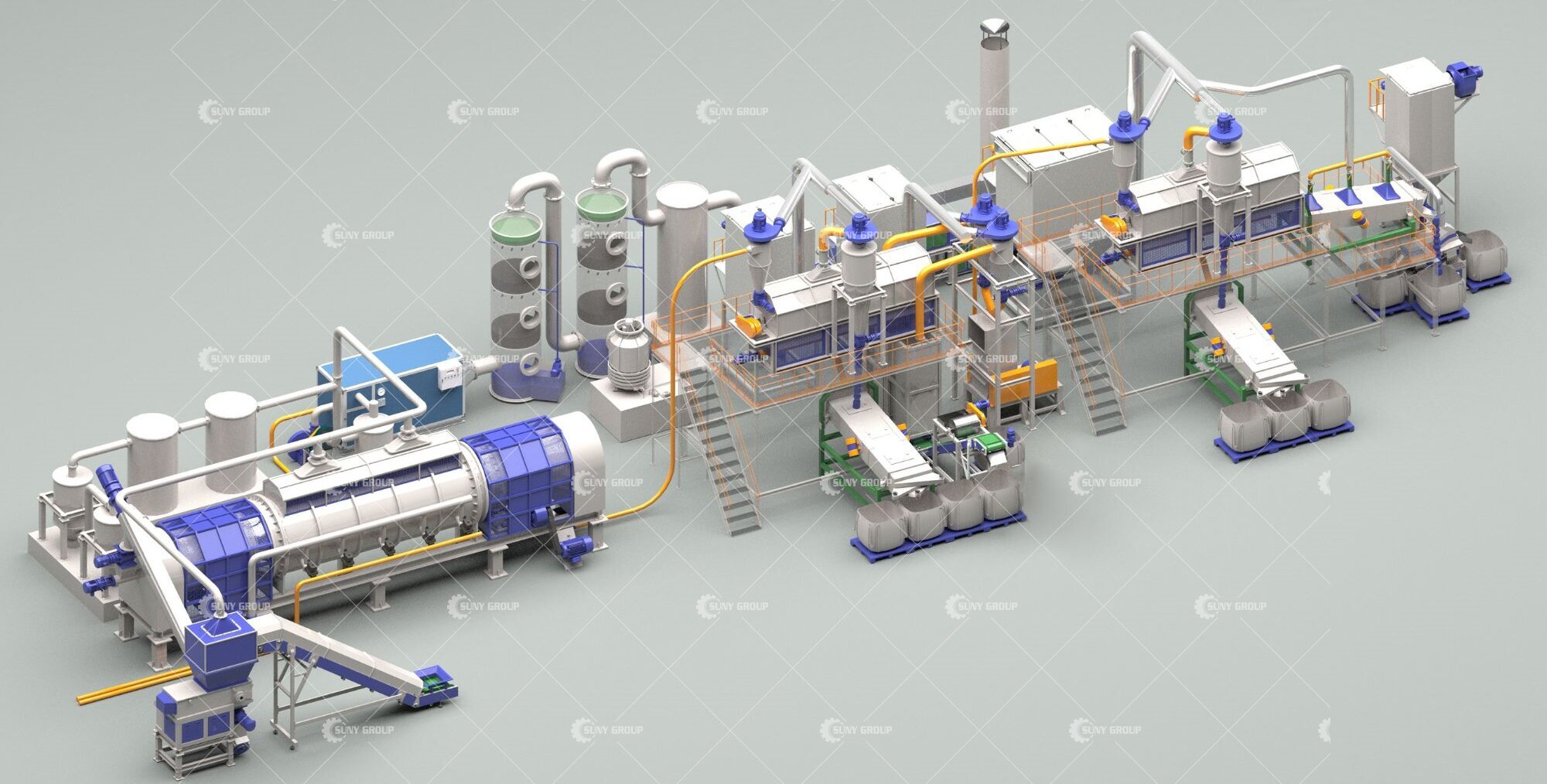

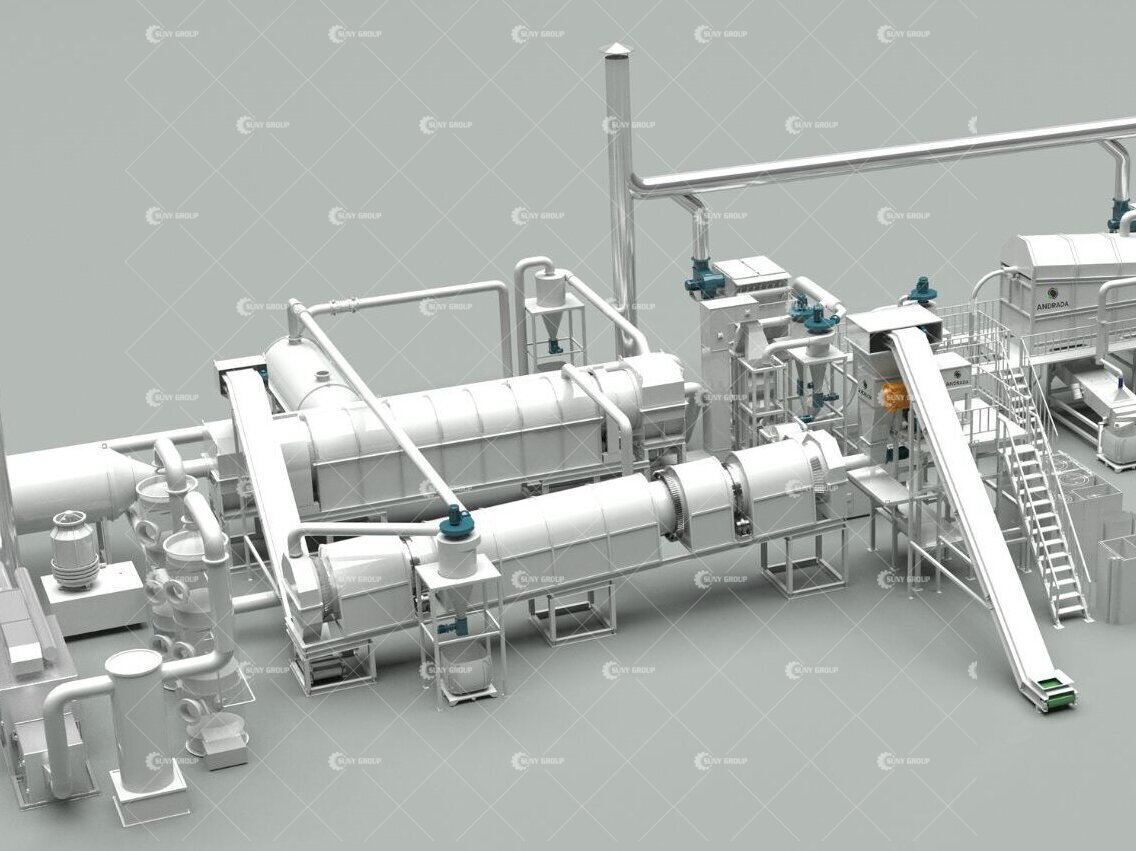

When Indian customers arrived, our professional technicians accompanied them to explain the principles and technical knowledge. We introduced the working principle, technical parameters and operation process of Lead Cupola Furnace in detail. Through diagrams and physical displays, the guests had a clear understanding of the structure and working principle of the lead smelting furnace, laying the foundation for subsequent visits and inspections.

Subsequently, Indian customers came to our factory workshop to personally visit and test run the Lead Cupola Furnace. Our technicians demonstrated the operating procedures and precautions of the lead smelting furnace for them, allowing them to operate it themselves and observe the operation of the equipment. In actual operations, our technical staff are ready to provide guidance and assistance to customers to ensure that they can fully understand the performance and characteristics of the equipment.

The two parties reached preliminary intentions on technical exchanges, equipment procurement and project cooperation. Our team welcomes customers from all over the world to contact us at any time, and we will provide you with the best quality Lead Cupola Furnace solutions with professional technology and services.

.png) Product Description

Product Description Model Number:

Model Number:  Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476