As the world continues to pay increasing attention to environmental protection and sustainable development, battery recycling has become an important way to solve the electronic waste problem. The wide range of applications of batteries, from household items to industrial equipment, provides us with convenience, but also brings the challenge of waste battery disposal. This article will introduce three common types of recyclable batteries and their main physical recycling processes.

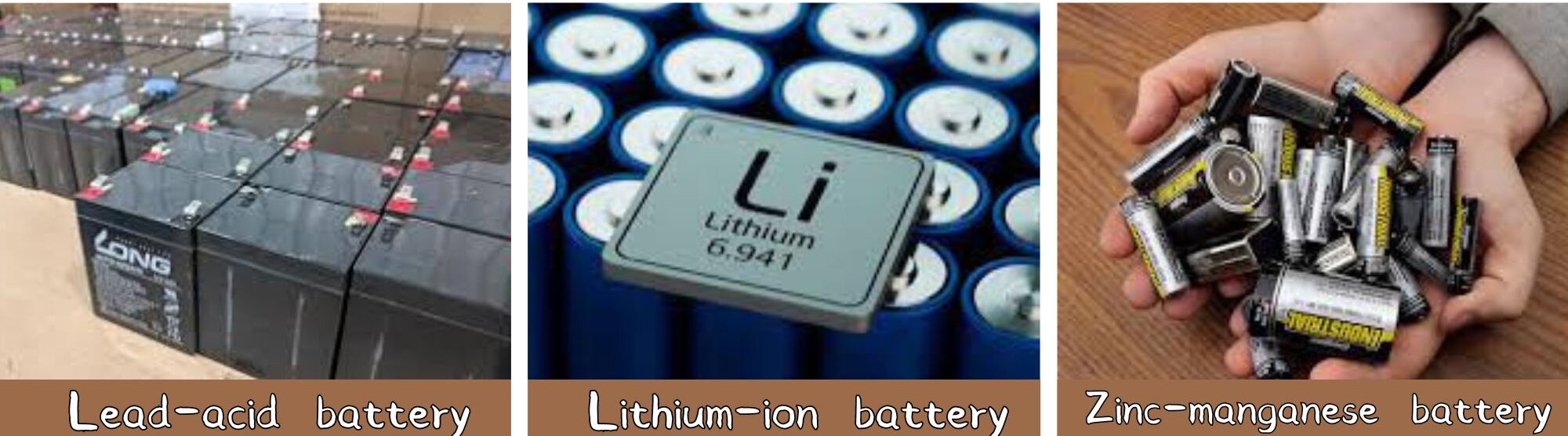

Type 1: Lead-acid battery

Lead-acid batteries are one of the earliest rechargeable batteries in the world and are widely used in car starting, backup power and industrial equipment. Because lead-acid batteries contain a large amount of lead and sulfuric acid, they have high recycling value, but improper disposal can cause serious pollution to the environment.

Type 2: Lithium-ion battery (Li-ion)

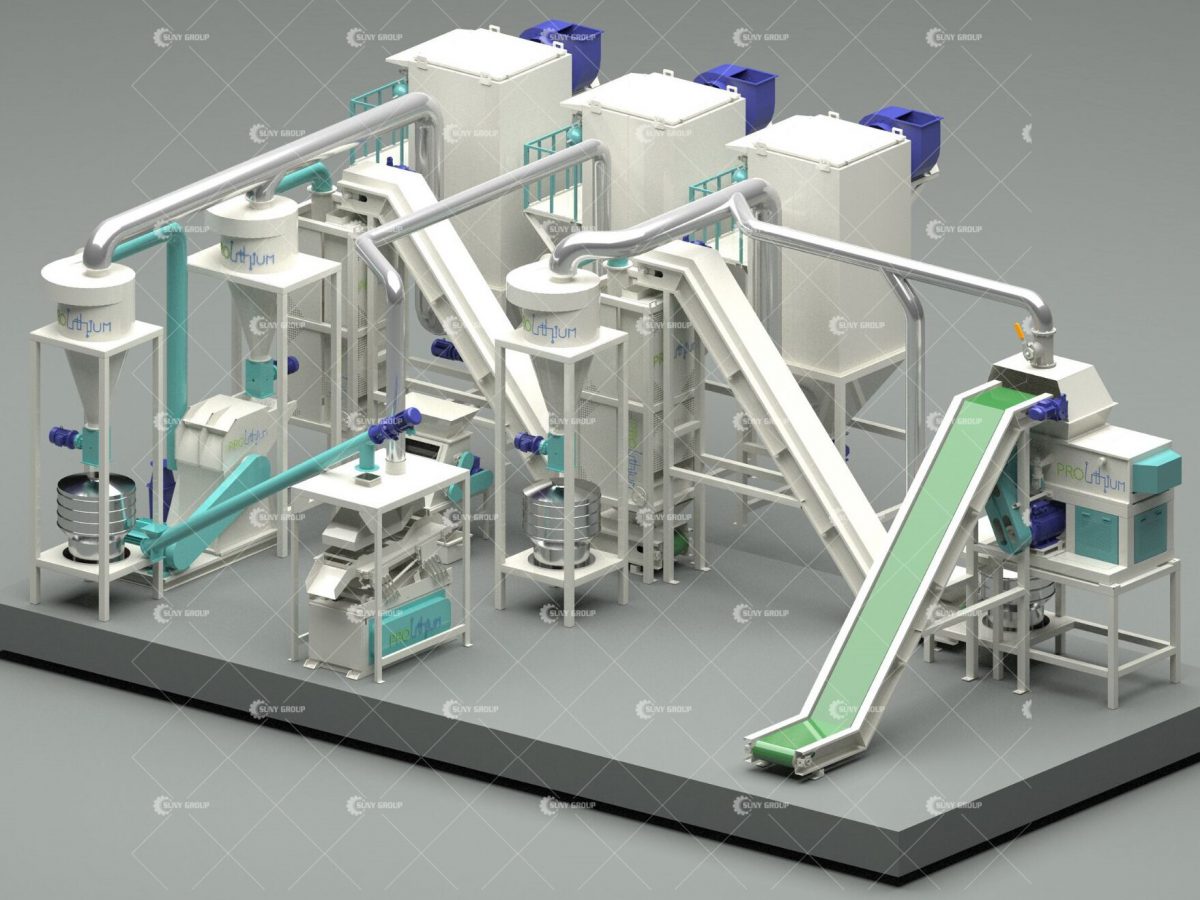

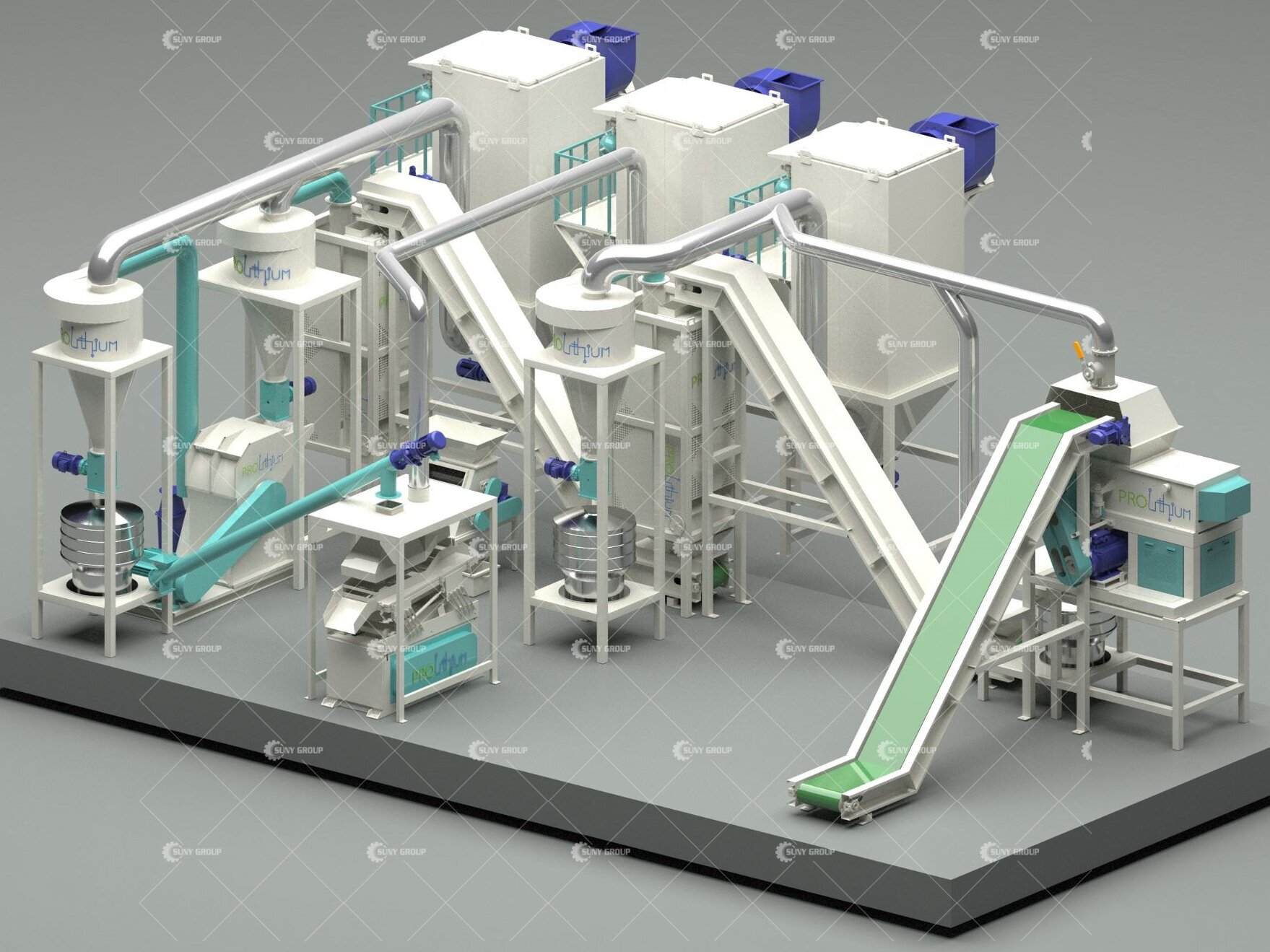

Lithium-ion batteries are widely used in mobile phones, laptops, electric vehicles and energy storage systems because of their high energy density, long life and portability. Because lithium-ion batteries contain precious metals such as lithium, cobalt, and nickel, their recycling can not only reduce environmental pollution, but also recover valuable resources.

Type 3: Zinc-manganese battery

Zinc-manganese battery is an alkaline battery, also known as alkaline zinc-manganese battery. It is a type of disposable battery, and common specifications include AA, AAA, etc. This kind of battery is usually used in some larger-power electronic devices, such as alarm clocks, toys, flashlights, etc.

The main processes of battery physical recycling:

1. The first step in battery recycling is to collect used batteries. There are usually dedicated battery recycling points in various places, or centralized collection through stores, schools, businesses and other channels. Some countries also have laws and regulations requiring manufacturers and sellers to collect and recycle used batteries.

2. The collected batteries are classified according to type. Different types of batteries have different recycling processes. Lead-acid batteries, lithium-ion batteries, zinc-manganese batteries, etc. all need to be processed separately to ensure that the recycling process is efficient and environmentally friendly.

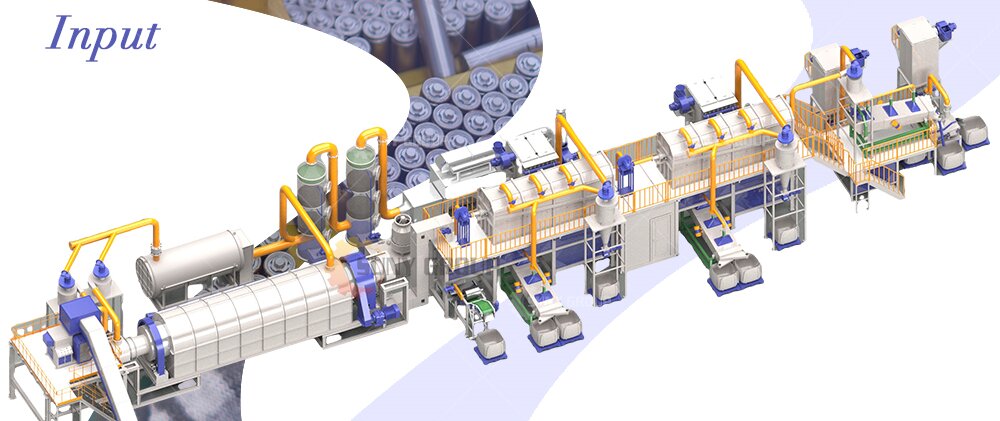

3. Before formal physical recycling, batteries need to be pre-processed, including discharge processing, disassembly, etc. Discharge processing is to ensure that the battery will not short-circuit or explode during processing, resulting in a fire and threatening the life safety of workers; disassembly is to separate different materials in the battery.

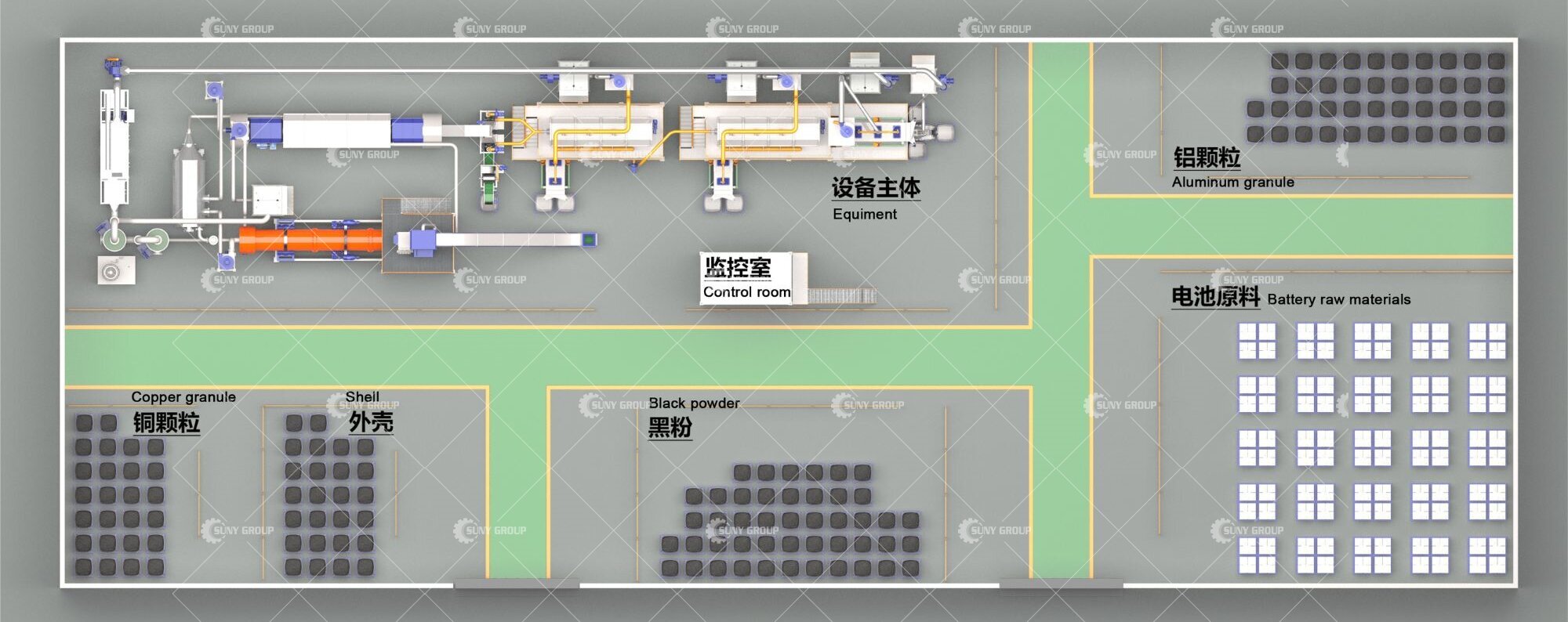

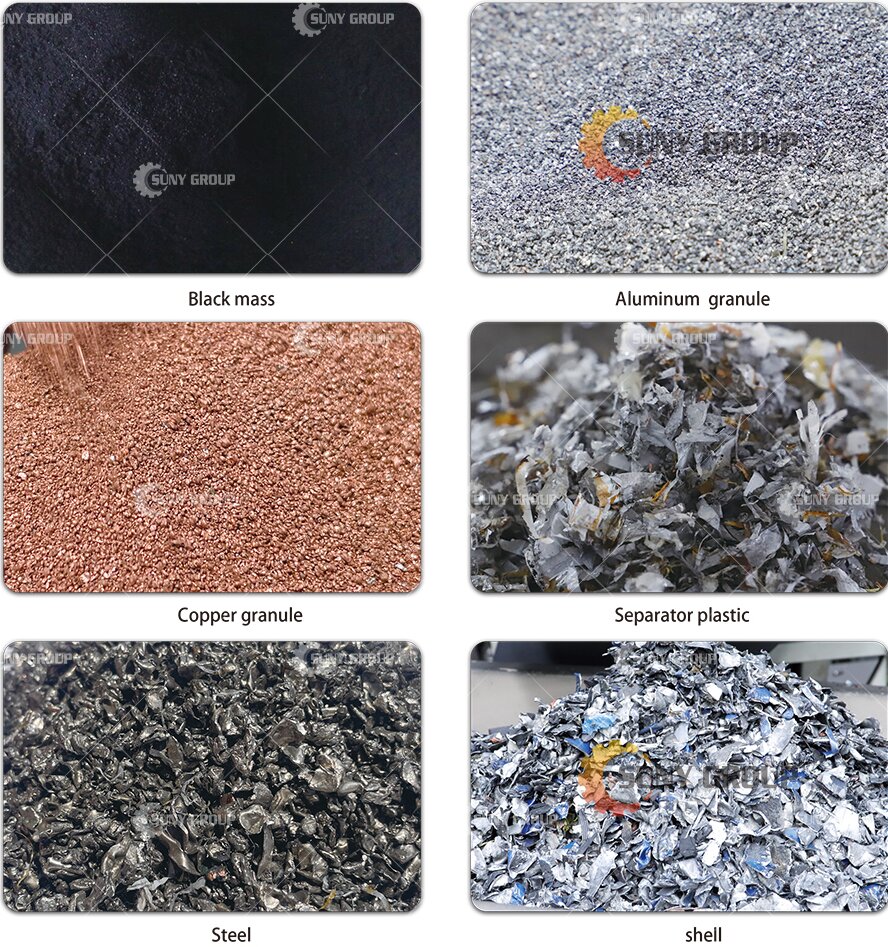

4. The pretreated battery enters the material separation and recycling stage. Different types of batteries use different methods for material separation. Lead-acid batteries usually separate lead, plastic and acid through physical and chemical methods; lithium-ion batteries use mechanical separation, including shredding, screening and separation, purification and dust removal, to recover lithium, carbon black, iron, copper, aluminum, etc. Materials that can be reused.

Battery recycling can not only effectively reduce the pollution of electronic waste to the environment, but also recover precious metal resources, achieve sustainable utilization of resources, and bring high-return economic benefits to recyclers. Therefore, in the global recycling market, battery recycling has always been the most important Popular recycling projects. Our team welcomes customers from all over the world to contact us at any time to discuss cooperation in battery recycling. If you are interested in our products and services, or have any questions, please do not hesitate to contact our team today.

.png) Product Description

Product Description Model Number:

Model Number:  Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476