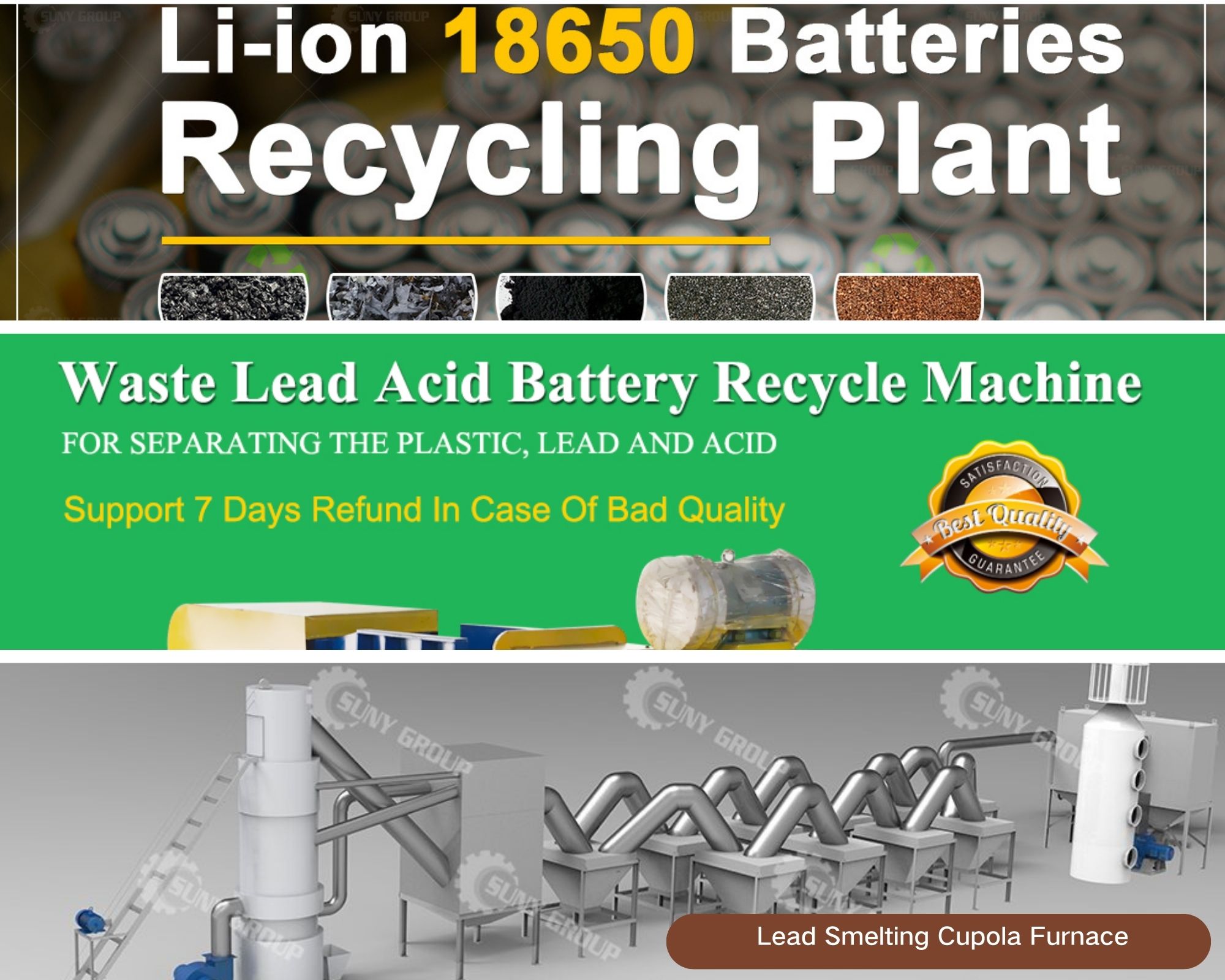

The current era is an era of economic globalization, an era of rapid changes in science and technology, an era of information technology, and an era of rapid change. For the lithium battery recycling industry, it is also an era full of opportunities. To unlock sustainable development, Suny Group has been committed to innovating lithium battery recycling technology and launched a series of innovative technologies, winning the trust of new and old customers. Please follow this article to learn about the latest lithium battery recycling technology.

In order to help recyclers new to this industry understand the sources and types of lithium batteries, we list here some common lithium batteries used in the recycling process. Electric vehicles, smartphones, computers, smart appliances, portable electronic devices, etc. all contain lithium battery. The popularity of these devices has brought great convenience, but it has also brought about a serious recycling and environmental problem: discarded lithium batteries. In the past, most of the discarded lithium batteries were buried underground with garbage, or burned directly, which not only had a serious impact on the environment, but also wasted a large amount of recyclable resources. Now this problem has been solved in a more scientific, effective and reasonable way – lithium battery recycling machine.

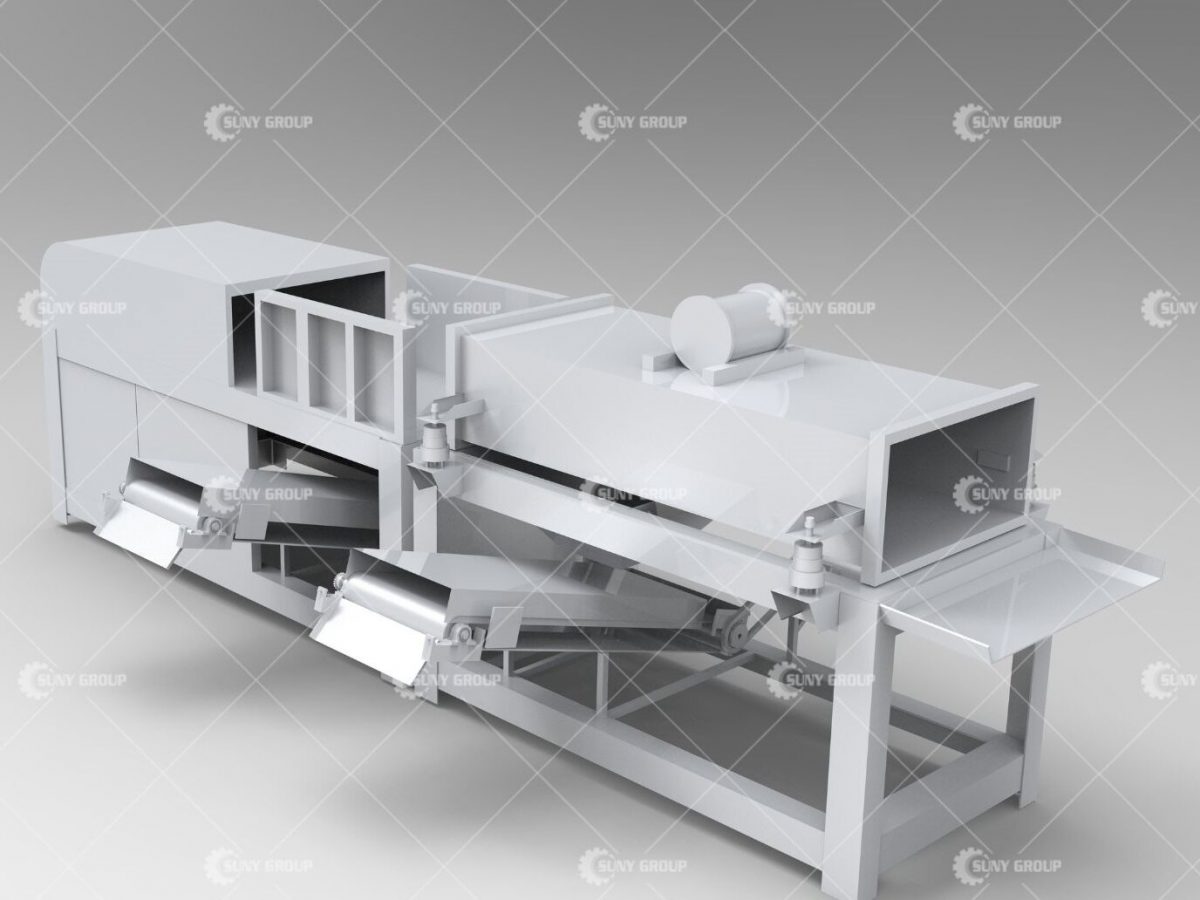

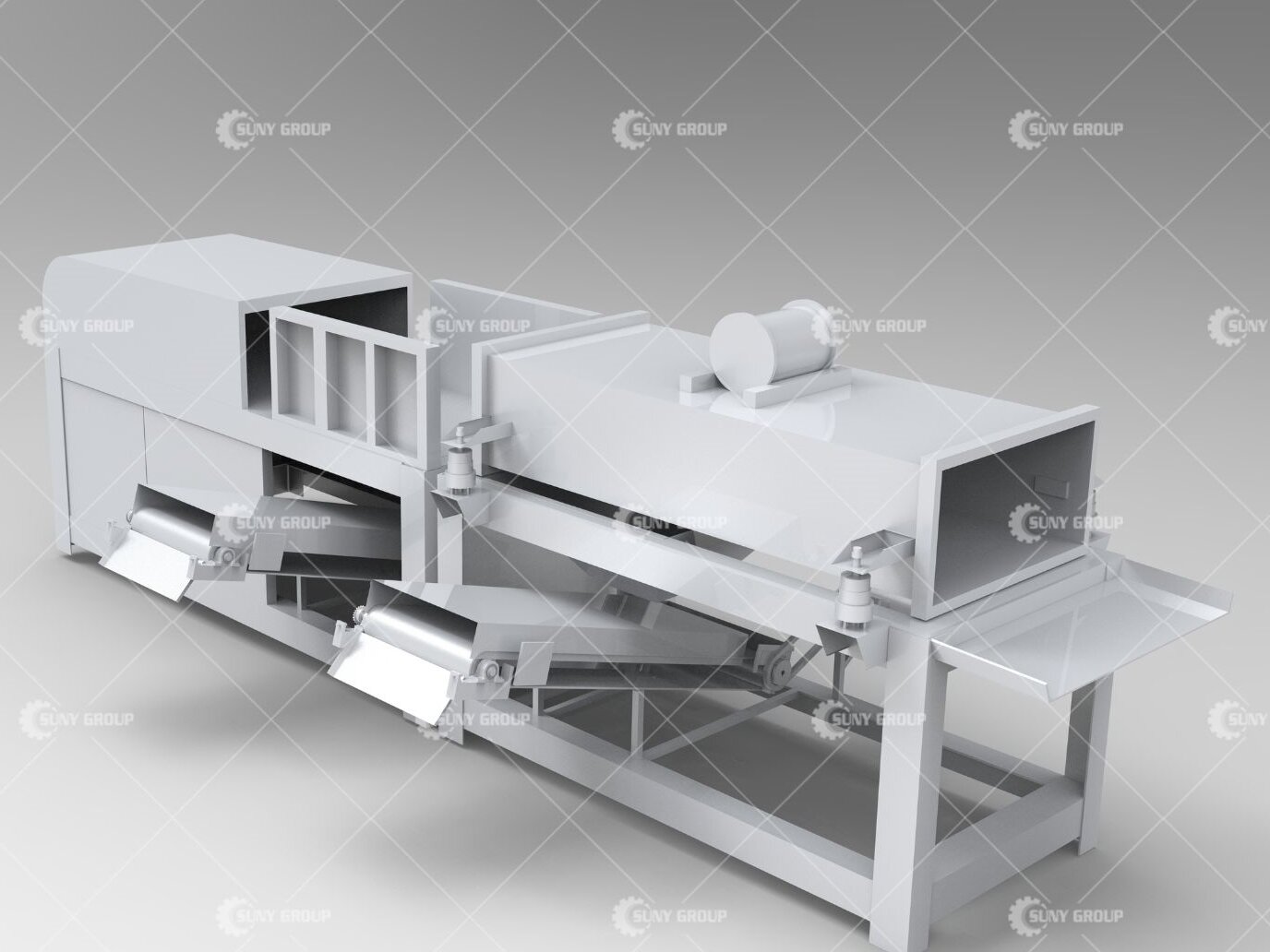

The technology of Suny Group’s lithium battery recycling machine mainly includes the following aspects:

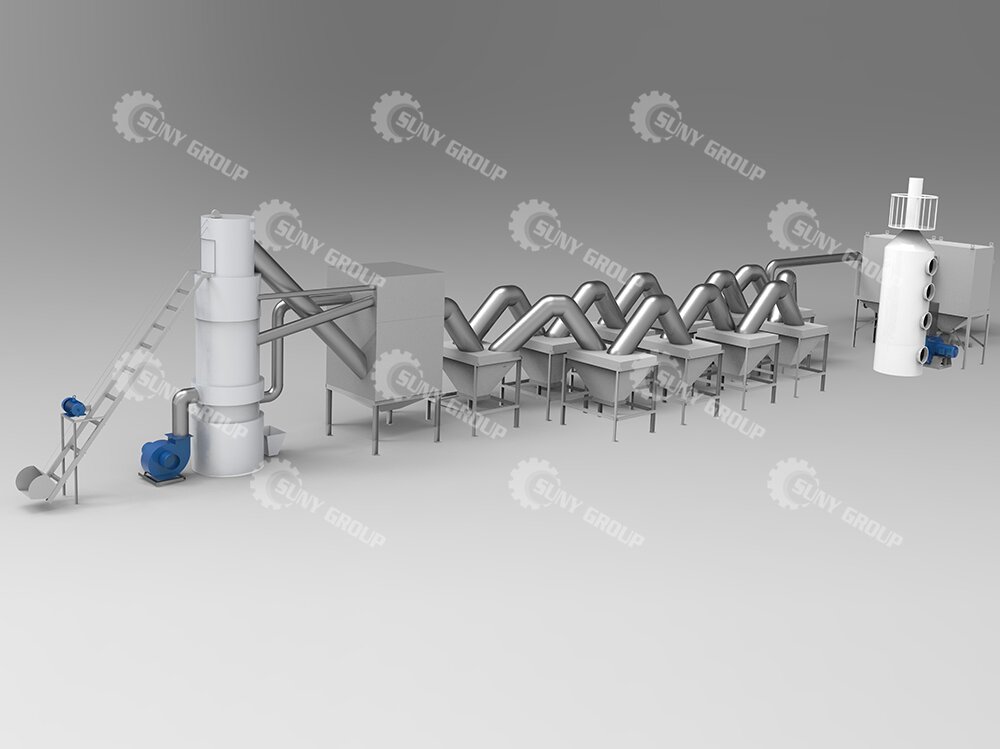

1. Efficient recycling technology: Suny Group is committed to converting used lithium batteries into reusable resources. We use an efficient recycling process to extract valuable metal elements such as lithium, cobalt, and nickel from used batteries. We can also obtain a large amount of battery carbon black with a purity of 99% for use in the production of new batteries or other products.

2. Safe treatment process: When dealing with used lithium batteries, safety is the first consideration. We adopt strict safety operating procedures and professional equipment to ensure that no harm will be caused to the environment and personnel during the recycling process. Equipped with a large number of safety protection measures to prevent production safety accidents.

3. Environmentally friendly processing: Our equipment attaches great importance to environmental protection and is committed to reducing the impact on the environment. During the lithium battery recycling process, we have adopted a series of environmental protection measures, including wastewater treatment systems, exhaust gas treatment systems, dust treatment systems, etc., to ensure that waste treatment meets environmental protection standards.

In addition to the advantages of these three dimensions, we also have more usage details to facilitate customers to quickly and skillfully operate the machine during the production process. Our team warmly welcomes customers from all over the world to contact us. We will provide you with customized lithium battery solutions to meet your needs with a professional attitude and rich experience. If you are interested in our lithium battery recycling products and services, or have any questions, please do not hesitate to contact our professional team today.

.png) Product Description

Product Description Model Number:

Model Number:  Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476