In the past 10 years, with the popularity of electric vehicles and portable electronic devices, the demand for lithium-ion batteries has increased significantly. However, the resulting battery waste problem has become increasingly severe and has become a top priority for environmental recycling in various countries. How to effectively recycle and reuse these lithium-ion batteries has become an important environmental and economic issue. SUNY GROUP will discuss with you the current technologies used to recycle lithium-ion batteries and briefly analyze the development trends in this field.

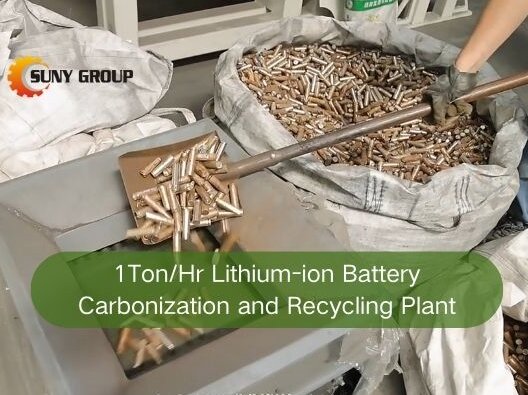

At present, the recycling of lithium-ion batteries mainly adopts the following technologies: 1. *Mechanical processing*: This method mainly includes crushing and screening, which mechanically decomposes the battery into smaller particles, and then separates them to obtain lron, Plastic Film, Black Mass, Aluminum, and Copper. The advantages of mechanical processing are simple process, low cost, environmental protection and high efficiency, fast technology upgrade, and stable mechanical equipment. It is the mainstream recycling technology for lithium-ion batteries in the world.

2. *Hydrometallurgy*: Hydrometallurgy is currently one of the most commonly used lithium-ion battery recycling technologies. This method extracts valuable metals such as lithium, cobalt, and nickel from batteries through chemical means such as acid leaching and solvent extraction. This method has a high metal recovery rate, but it requires the treatment of a large amount of chemical waste liquid, which has a certain impact on the environment, is costly, inefficient, and has a limited scope of application.3. *Pyrometallurgy*: Pyrometallurgy extracts metals from batteries through high-temperature smelting. The advantages of this method are fast processing speed and high metal recovery rate, but the disadvantages are high energy consumption and the generation of harmful gases during the treatment process, which not only pollutes the environment but also has a certain impact on workers.

With the enhancement of environmental awareness and the promotion of policies, the lithium-ion battery recycling industry presents the following major development trends: 1. *Policy promotion*: Governments of various countries have introduced policies to encourage the recycling and reuse of lithium-ion batteries. For example, the European Union issued the “Battery Directive” in 2020, requiring member states to increase the recycling rate of batteries and imposing stricter recycling responsibilities on battery manufacturers. China also issued the “Management Measures for the Recycling of Waste Batteries” in 2021, clarifying the extended producer responsibility system and encouraging enterprises to establish a recycling system.

2. *Extension of the industrial chain*: More and more battery manufacturers and automakers are beginning to get involved in the field of battery recycling, forming a complete industrial chain from production to recycling. For example, companies such as Tesla and CATL have established their own battery recycling systems to ensure that used batteries can be effectively recycled and reused.3. *Growth in market demand*: With the development of electric vehicles and renewable energy, the demand for lithium-ion batteries will continue to grow. It is expected that by 2030, the global lithium-ion battery market will reach hundreds of billions of dollars. This will further promote the development of the battery recycling industry, drive the advancement of recycling technology and improve the recycling system.4. *Enhanced environmental awareness*: With the improvement of public environmental awareness, more and more consumers are willing to choose environmentally friendly products and support battery recycling. This provides a good social foundation for the development of the battery recycling industry.

In general, lithium-ion battery recycling technology is constantly improving, and the recycling industry is also developing rapidly. Policy promotion, technological innovation, extension of the industrial chain, growth in market demand, and enhanced environmental awareness are all important factors driving the development of this field. In the future, with the further maturity of technology and the improvement of the recycling system, lithium-ion battery recycling will become an important environmental and economic field, contributing to sustainable development. Among the main recycling technologies at present, mechanical processing recycling (lithium ion battery recycling machine) is still the choice of more than 90% of recyclers. Choose us, contact us, and take action now!