In the pursuit of environmental protection and resource reuse, lithium battery recycling has become the focus of global attention. As a leader in the field of lithium battery recycling, Suny Group has recently launched an innovative process to bring lithium battery recycling to a new level and add another touch of glory to the cause of green environmental protection.

Suny Group’s new process includes the following key steps:

1. Shredder: First, the used lithium batteries are sent to the shredder to be shredded into small pieces.

2. Hammer crusher: Next, the shredded materials are sent to the hammer crusher for secondary crushing and separation to further refine the materials.

3. Crusher: The crushed materials are sent to the pulverizer for crushing treatment to achieve a finer particle size.

4. Separator: The crushed materials are separated by wind through the analysis machine to separate valuable metal elements from other materials.

5. Collector: The separated metal elements are collected and discharged through the induced draft fan to ensure resource reuse and environmental protection.

6. Pulse purifier: The dust in the entire equipment is purified by the pulse purifier to ensure a clean production environment.

7. Classification screen: The materials sorted by the analysis machine are sent to the classification screen for screening, and large metal materials are sorted out.

8. Magnetic separator: The magnetic separator separates the nickel from the metal and provides pure metal materials for subsequent processing.

9. Specific gravity sorting machine: The fine materials that have been sorted and screened are then sorted by specific gravity to completely separate metals and other materials.

10. High-pressure fan: The entire system is in a negative pressure state, collecting powder and purifying the air to ensure a clean production environment and employee health.

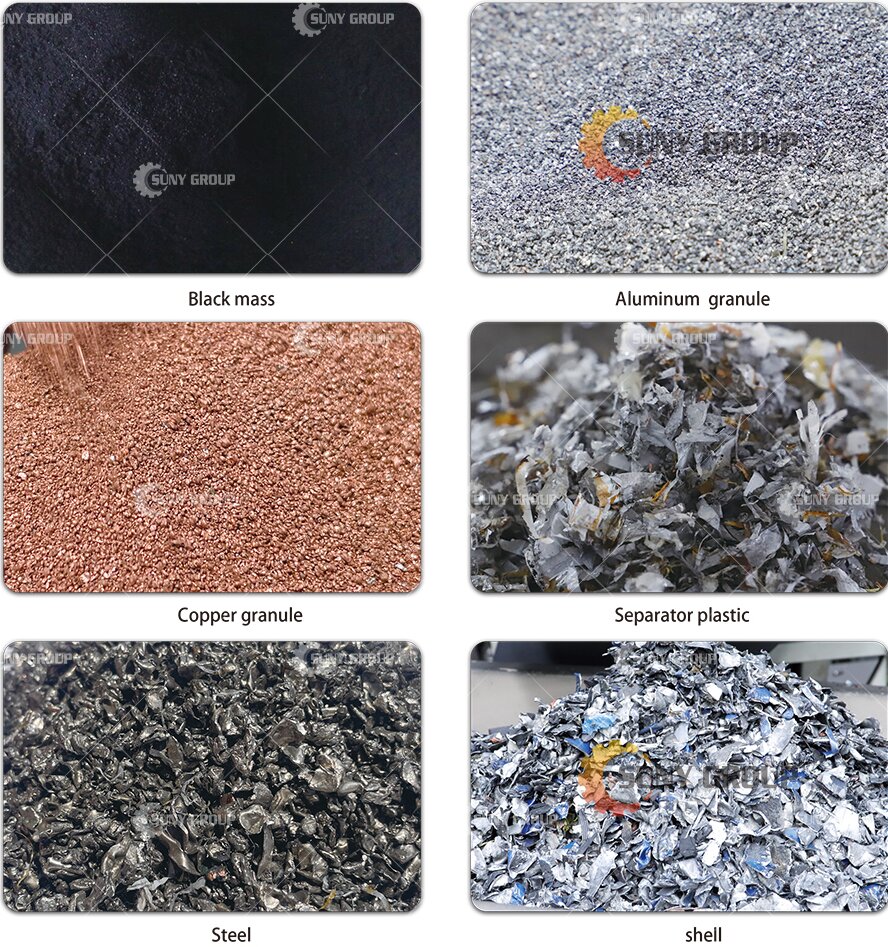

This innovative process not only improves the efficiency and quality of lithium battery recycling, but also greatly reduces environmental pollution and achieves sustainable use of resources. In Suny Group’s process, the main materials recovered from used lithium batteries include: Black mass, Aluminum granule, Copper granule, Separator plastic, Steel, and shell.

Our team sincerely welcomes customers from all over the world to contact us. We will provide you with the most satisfactory solutions with professional technology and services. Contact us now and let us work together to create a broader future for lithium battery recycling!