The effective recycling of used batteries has always been a powerful obstacle that confuses major recyclers in efficient recycling. Among various recyclable batteries, lead-acid batteries are one of the most difficult to efficiently recycle due to their hard shell and corrosive electrolyte solution, which makes recycling more difficult. Lead-acid batteries are currently the largest and most widely used battery type in the world. Of the world’s annual lead production, lead-acid batteries in automobiles, industrial facilities and portable tools often account for 75% of the world’s total lead consumption. Developed countries in the world attach great importance to the recycling of secondary lead. Understanding the current challenges faced by lead-acid battery recycling, our professional technicians stepped up to the challenge, overcame various technical difficulties, and finally achieved innovative upgrades in recycling technology. Please follow this article to explore new solutions for lead-acid battery recycling.

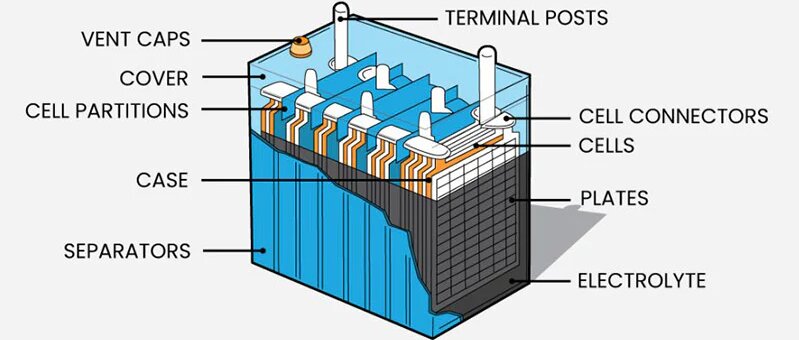

The picture above is a schematic structural diagram of most lead-acid batteries, allowing you to understand the various components of lead-acid batteries. During the recycling process, we need to obtain plastic casings, electrolyte solutions, lead (lead plates and lead grids), and some copper, iron and other metals from used lead-acid batteries. To obtain these usable and valuable materials, the old technical solution was to rely on manual labor. Usually mechanical cutting or manual disassembly is used. Care is required during disassembly to prevent electrolyte leakage. After disassembly, the different components in the battery are separated, including the lead plate, lead grid, plastic casing, and electrolyte. Manual dismantling and recycling solutions are too inefficient, costly and dangerous. Our technicians, through technological research and development, have designed and manufactured automated machines to recycle lead-acid batteries. Please see the YouTube video below for the specific process.

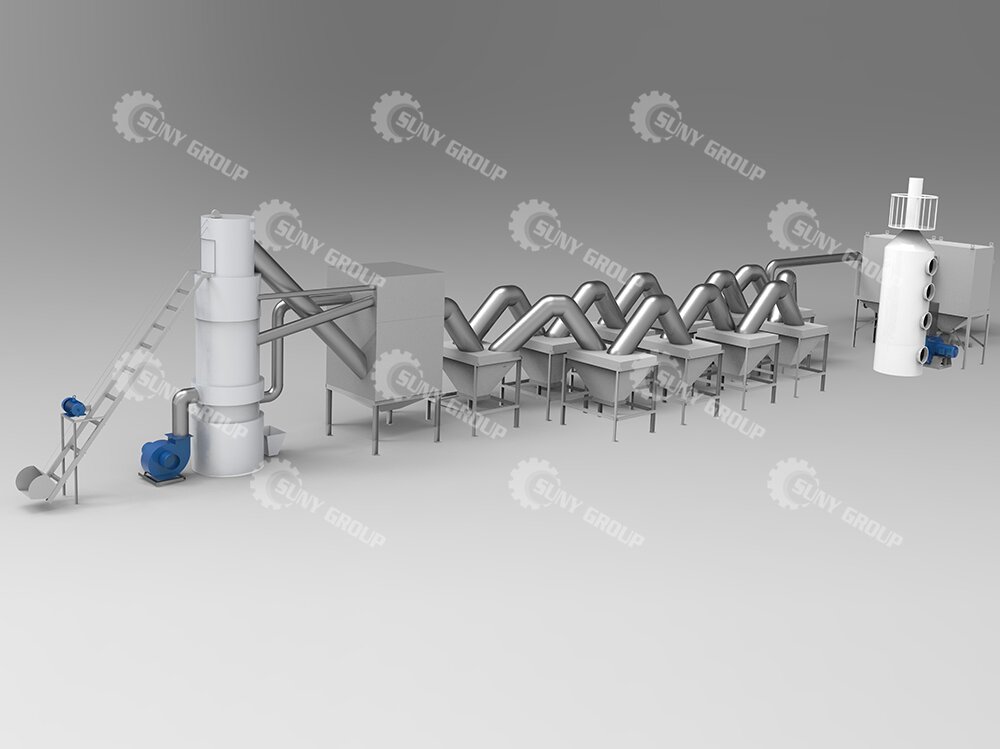

In order to improve the purity of lead (lead plates and lead grids), this part of the material will be melted by the Lead Smelting Cupola Furnace, and the impurities will be removed to obtain pure lead, which will then be made into lead ingots and shipped to the manufacturer for reuse and manufacturing. New batteries or items containing lead.

The launch of the lead-acid battery separation and recycling machine and the Lead Smelting Cupola Furnace marks a new milestone in the lead-acid battery recycling industry. I believe that with the continuous advancement of science and technology and the improvement of environmental awareness, this technology will play an increasingly important role in the future. If you are interested in our products and services, or have any questions, please do not hesitate to contact our team today. We will wholeheartedly provide you with professional solutions and provide you with the best quality service.

.png) Product Description

Product Description Model Number:

Model Number:  Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476