Lead-acid batteries, as they are widely used in automobiles, electronic devices, and energy storage systems, will have a serious impact on the environment if they are not properly disposed of after use. Leakage of lead and acid will not only contaminate soil and water but also pose a hazard to human health. Therefore, it is particularly important to establish an efficient recycling system, and battery separators play a vital role in this process.

lead acid battery recycling machines

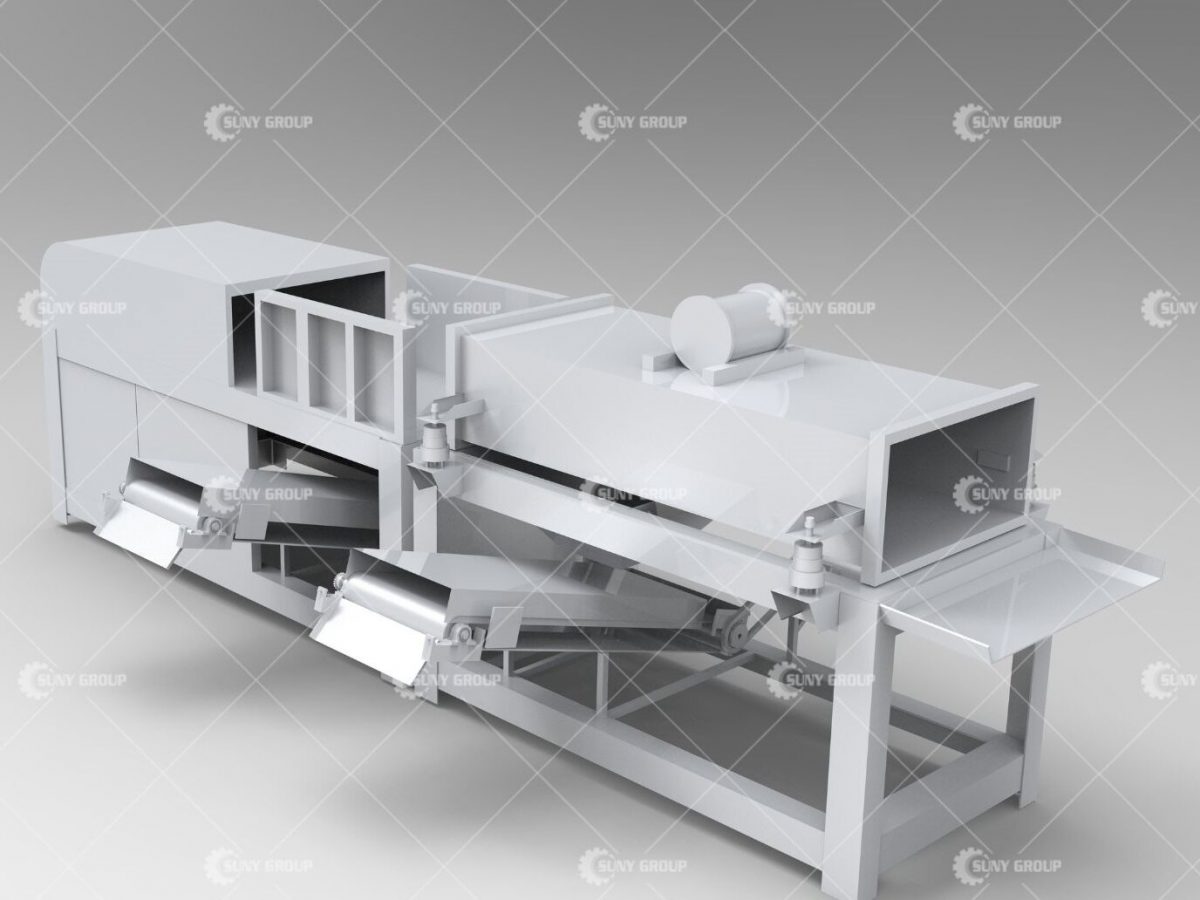

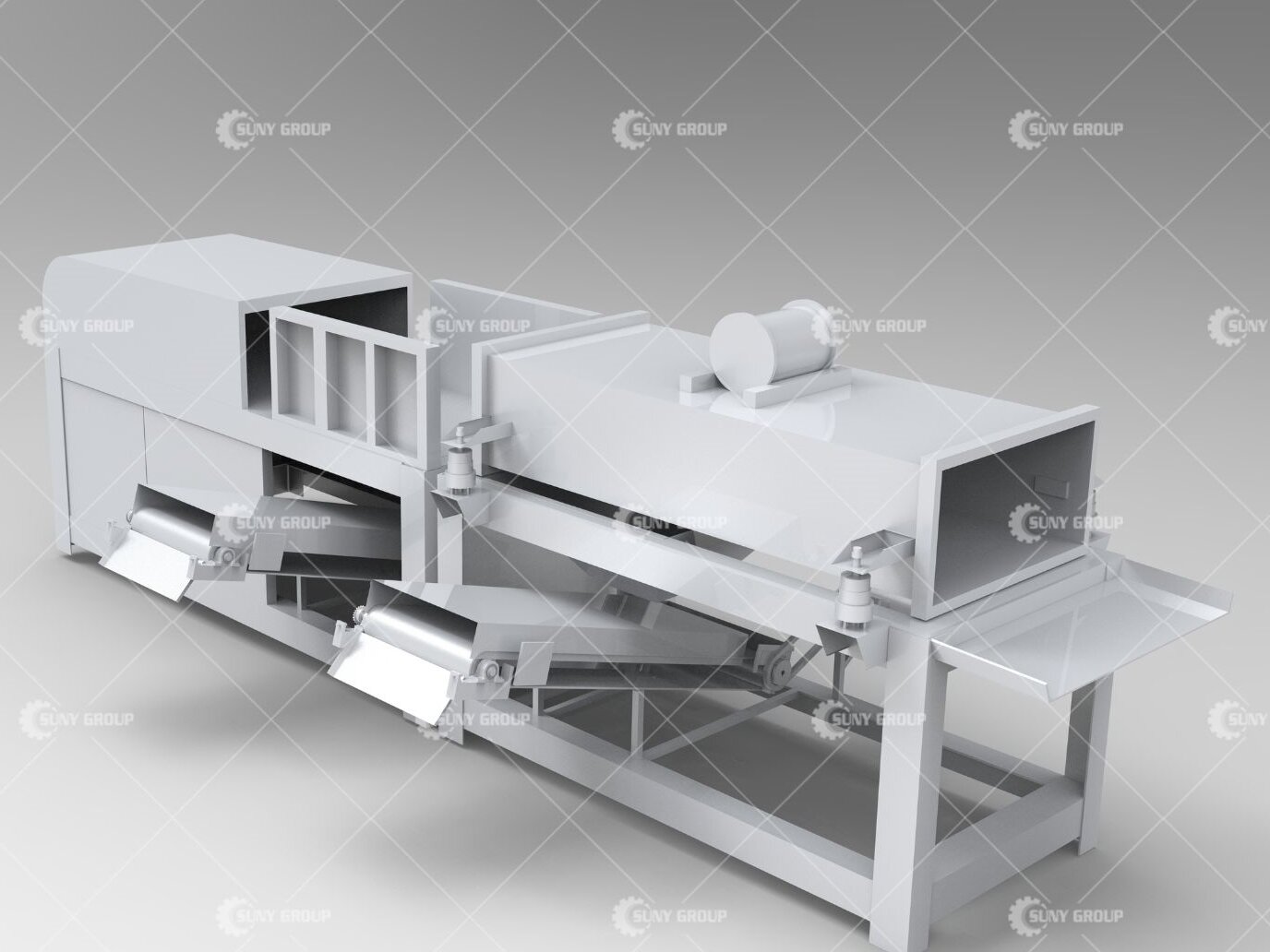

The main function of the lead-acid battery dismantling and recycling line is to separate the waste lead-acid batteries efficiently, and ultimately produce reusable resources such as plastic, lead, and acid. It works by physically separating the internal components of the battery by mechanized means. Specifically, the machine feeds the waste batteries into the separation area where, after a series of treatments, the recovered plastics can be reprocessed, the lead can be sent to the smelting section for refining, and the acid can be rendered harmless according to the treatment requirements. If deeper recycling is required, the crude lead can also be smelted in a cupola furnace to obtain high-purity lead ingots. In addition, the melting process is equipped with an air pollution purification system, which can effectively filter and treat harmful gases, in line with the current environmental policy.

lead acid battery recycling machines

The design of the lead-acid battery separator features full automation, which greatly saves manpower costs. Operators only need to carry out simple monitoring and maintenance of the equipment to achieve 24-hour uninterrupted operation. With its reasonable structural layout and stable performance, it can cope with large-scale waste lead-acid battery processing needs. At the same time, the installation of the production line is very convenient and can be flexibly configured according to the needs of the actual site. Whether in factories, warehouses, or outdoor environments, the lead-acid battery separator can be effectively adapted to ensure efficient recycling.

In summary, the battery separator plays an indispensable role in the recycling and treatment of waste lead-acid batteries. Through efficient separation technology, fully automated workflows, and environmentally friendly processing methods, we are not only able to effectively address the environmental challenges posed by lead-acid batteries but also open up new paths for the sustainable use of resources.

.png) Product Description

Product Description Model Number:

Model Number:  Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476