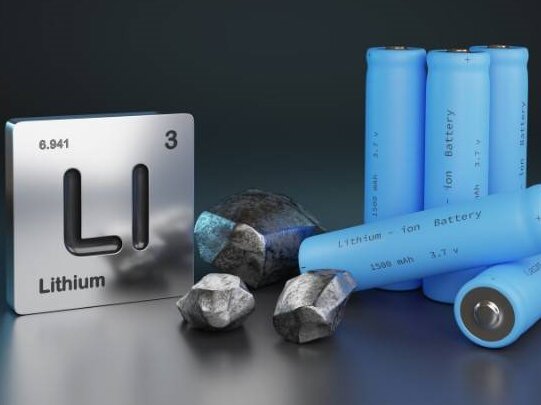

Thailand, this exotic country, is the pearl of Southeast Asia and a region where the environmental protection industry is developing rapidly. Recently, we were fortunate to welcome important customers from Thailand. They showed strong interest in lithium battery recycling equipment and learned about the quality of our equipment and stable after-sales service through other recyclers, so they came here specially. Our company visited our production workshop on site. During this special inspection and exchange, our team accompanied us throughout the entire process, demonstrating our professional skills and excellent quality to our customers.

This customer from Thailand represents a company with a good reputation in the environmental protection industry. They are very concerned about the performance and effect of lithium battery recycling equipment. By understanding our equipment quality and service advantages, they hope to establish a long-term and stable cooperative relationship with us, introduce advanced equipment technology, and enhance the company’s competitiveness in the field of environmental protection.

In communicating with customers, we learned that customers have high expectations for our equipment performance and after-sales service. Therefore, we have made sufficient preparations in advance to ensure that we can fully demonstrate our production process and equipment performance to customers, as well as our commitment and guarantee in after-sales service.After the customer arrived at our company, we arranged a full visit and communication activities. We first introduced our company’s production process and equipment technology to customers, and explained in detail the working principle, operating procedures and technical characteristics of the equipment. Through on-site demonstrations and illustrated explanations, customers have a comprehensive understanding of our production processes and equipment performance.

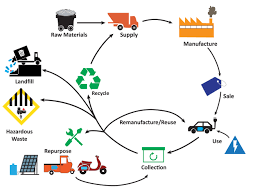

During the visit, we focused on demonstrating the performance and effects of our lithium battery recycling machine equipment. Through physical displays and on-site demonstrations, we showed customers the crushing, separation and recycling process of the equipment, allowing them to witness the working efficiency and stability of the equipment with their own eyes. Customers expressed high satisfaction with the performance of the equipment and fully affirmed our technical level and production capabilities.