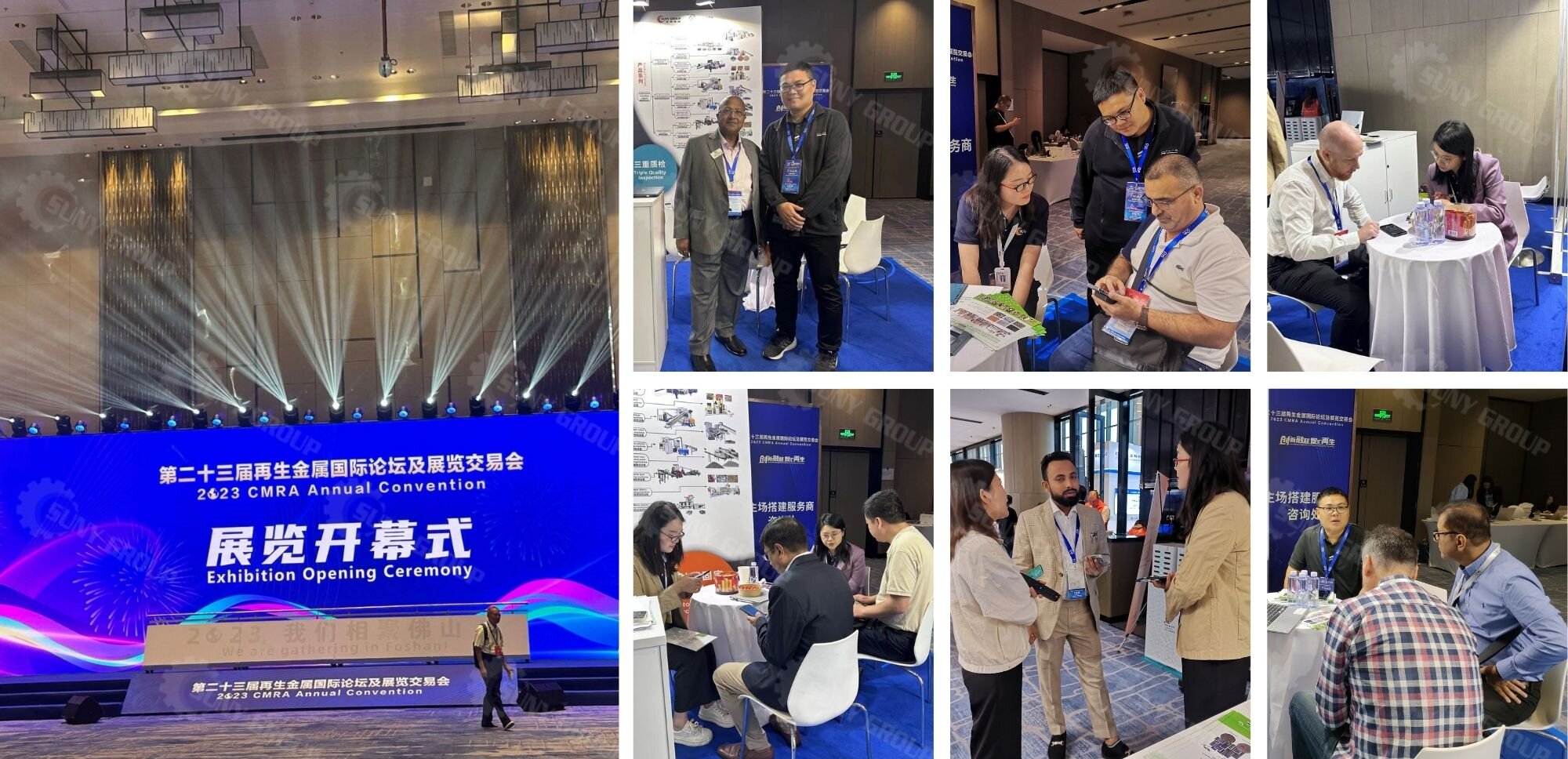

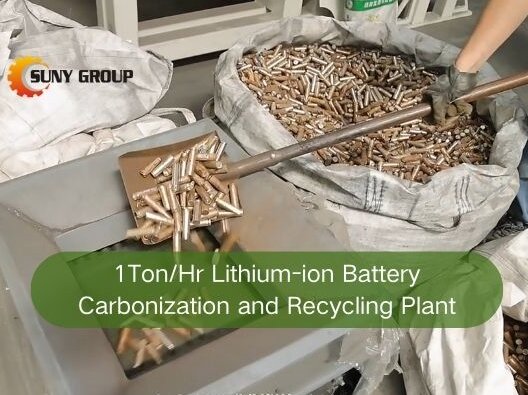

SUNY GROUP is an influential enterprise in the field of recycling equipment for waste batteries (lithium batteries, lead-acid batteries, high manganese batteries, button batteries, and Soft Pack (NMC) lithium batteries). Relying on a professional team, cutting-edge technology, and precise market insights, SUNY GROUP has built up a global business territory of efficient battery recycling machines and has gained the reputation of high-quality and sustainable solutions, which have won the trust of our partners. SUNY GROUP has confirmed that it will participate again in the three exhibitions of ReMA 2025, which are highly anticipated, to show the latest battery recycling technology solutions!

1. ReMA 2025

May 12-15, 2025, the San Diego Convention Center will become the focus of the global waste recycling industry, ReMA 2025 Convention & Exposition grand opening, SUNY GROUP as a recycling equipment industry leader, will bring its lithium-ion batteries, lead-acid batteries crushing production line and other waste battery recycling equipment in the field of revolutionary technology and innovation returns. SUNY GROUP, as the leader of the recycling equipment industry, will bring its revolutionary technology and innovative achievements in the field of lithium-ion batteries, lead-acid battery crushing production lines, and other waste battery recycling equipment.

2. Waste-Tech 2025

When the time comes to September 9-11, 2025, the Krokus International Exhibition Center in Moscow, Russia, will usher in the annual event in the field of environmental protection – Waste-Tech. SUNY GROUP has come to the exhibition prepared for this time, aiming to become the core promoter of the environmental protection and recycling of waste batteries and technological innovation. The integrated solution for solid waste battery processing on display is like a “green processing plant”, which efficiently transforms waste into treasure, and gets valuable materials such as black powder (lithium, cobalt, nickel, etc.), lead, copper, aluminum, etc. through recycling of waste batteries.

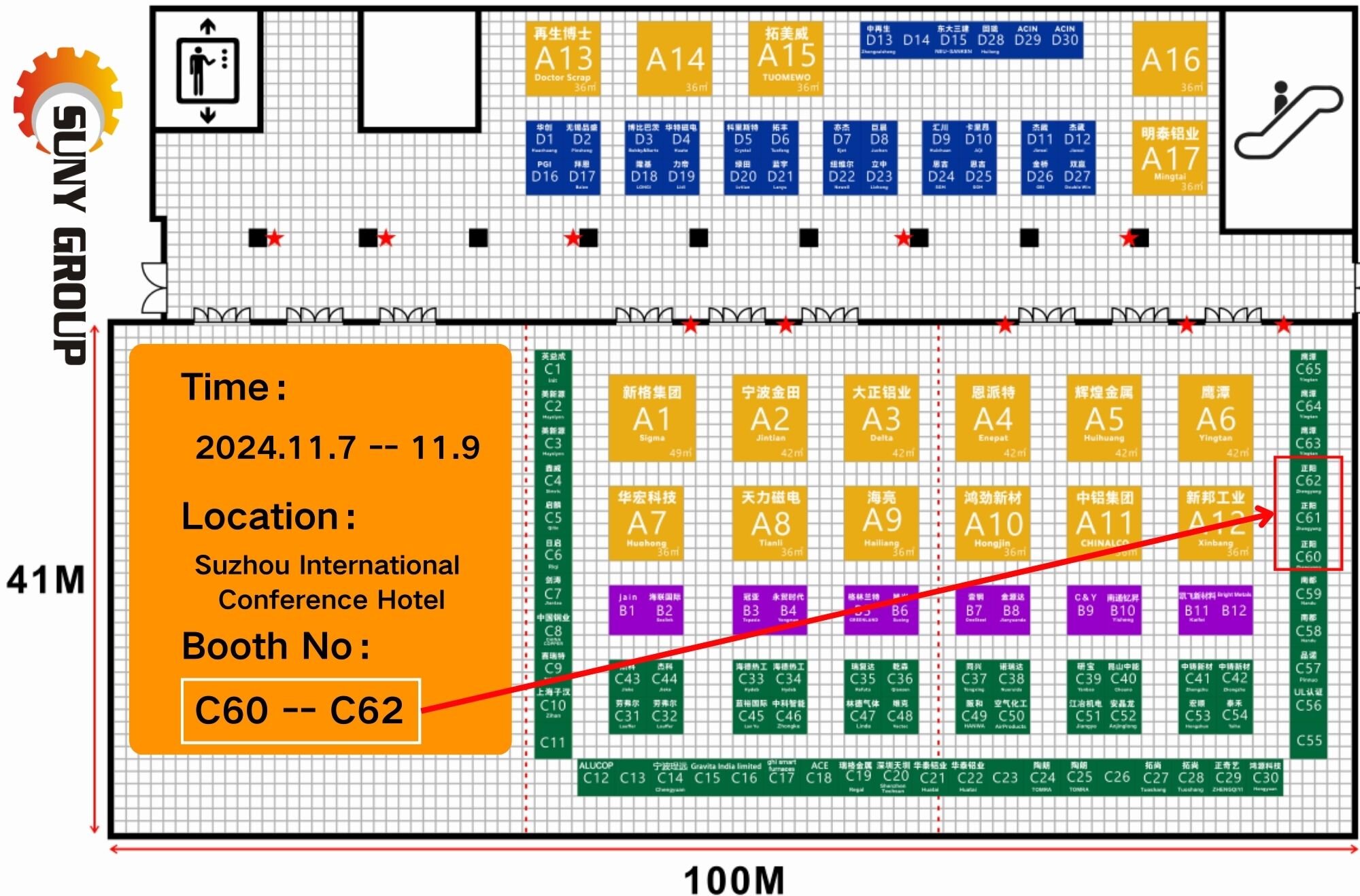

3. CMRA Annual Convention 2025

November 7 – 9, 2025, Chengdu, China will gather the global recycled metal industry’s attention, the 25th China Nonferrous Metals Industry Association Recycled Metals Branch Annual Convention will be held grandly. We will display our self-developed super-efficient recycled metal refining process, which is like the “gold-dotting” in the field of metal recycling, dramatically improving the metal recovery rate and purity; lead smelting equipment, lead ingot casting equipment, and so on!

What is more, expected is that SUNY GROUP has more exhibition layouts to follow, and we look forward to meeting you at these exhibitions to learn more about the battery recycling machines and equipment you are interested in. If you would like to get a quote and details of the machines immediately, please contact us!

Contact Tel: +86 199 0388 6476

Contact Email: zyunfei87@gmail.com