South Korean investors have recently shown strong interest in the lithium battery recycling technology of China’s SUNY GROUP, with a focus on inspecting and purchasing automotive lithium battery recycling lines. During the visit, the South Korean investors paid special attention to SUNY GROUP’s technological advantages and innovation potential in the field of lithium battery recycling, which is known for its advanced automated recycling equipment and high-purity material extraction technology, which significantly improves the recycling efficiency and reduces the operating costs. These technological innovations have made SUNY GROUP a leader in the industry and attracted the attention of South Korean investors.

The background to the South Korean investor’s visit was the continued growth in global demand for lithium batteries, particularly in the electric vehicle industry. With the popularity of electric vehicles, the recycling and reuse of lithium batteries has become particularly important. South Korean companies hope to improve their competitiveness in the new energy sector by introducing advanced recycling technologies.

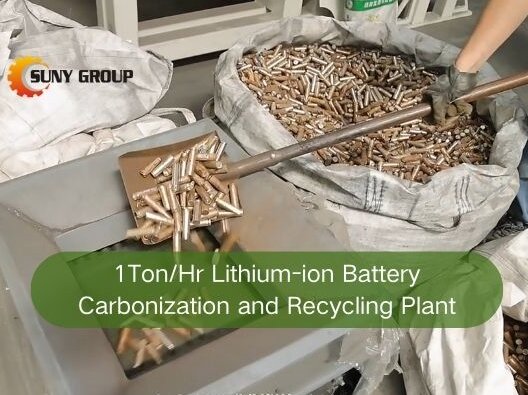

During the visit, the South Korean investors learned more about SUNY GROUP’s lithium battery recycling technology and solutions. Among them, the automated recycling equipment demonstrated the ability to efficiently decompose and extract battery materials, ensuring that the extracted materials are pure and suitable for reuse. These technologies not only improve recycling efficiency but also reduce the impact of waste on the environment. SUNY GROUP’s advantages in improving recycling efficiency and reducing costs are particularly outstanding. This technological advantage makes SUNY GROUP an ideal partner for South Korean investors.

At the end of the visit, South Korean investors spoke highly of SUNY GROUP’s lithium battery recycling technology. They were impressed by the advancement and operability of the technology and expressed their willingness for further cooperation. By introducing SUNY GROUP’s advanced technology, South Korean lithium battery recycling companies are expected to occupy a favorable position in the future market competition, and at the same time contribute to the global environmental protection cause. If you are interested in our products and services or have any questions, please do not hesitate to contact our team.