Recently, our company has welcomed a group of important customers from Romania. Mr. Li led a technical inspection team to our processing workshop to have an in-depth discussion on the technical characteristics, operating details, and replacement of accessories of the lithium battery recycling machines. Through on-site explanations and exchanges, the customer had a deep understanding of our technical strength and successfully purchased our lithium battery recycling machine.

Mr. Li represents an electronic waste environmental recycling company in Romania. They plan to introduce advanced lithium battery recycling machine equipment to enhance the company’s competitiveness in the environmental protection field and make greater contributions to Romania’s local battery recycling industry. Therefore, they decided to come to our processing workshop for on-site inspection and gain an in-depth understanding of our technology and products in order to make purchasing decisions.

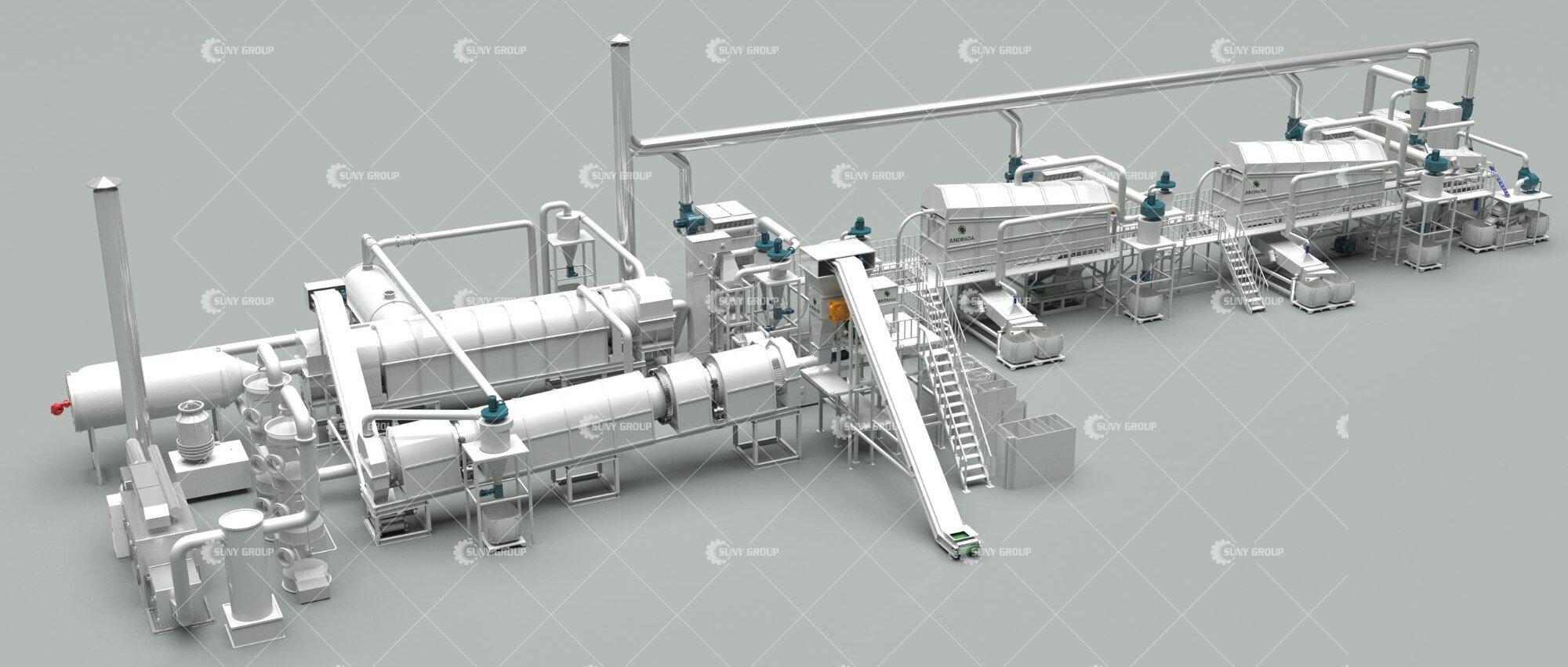

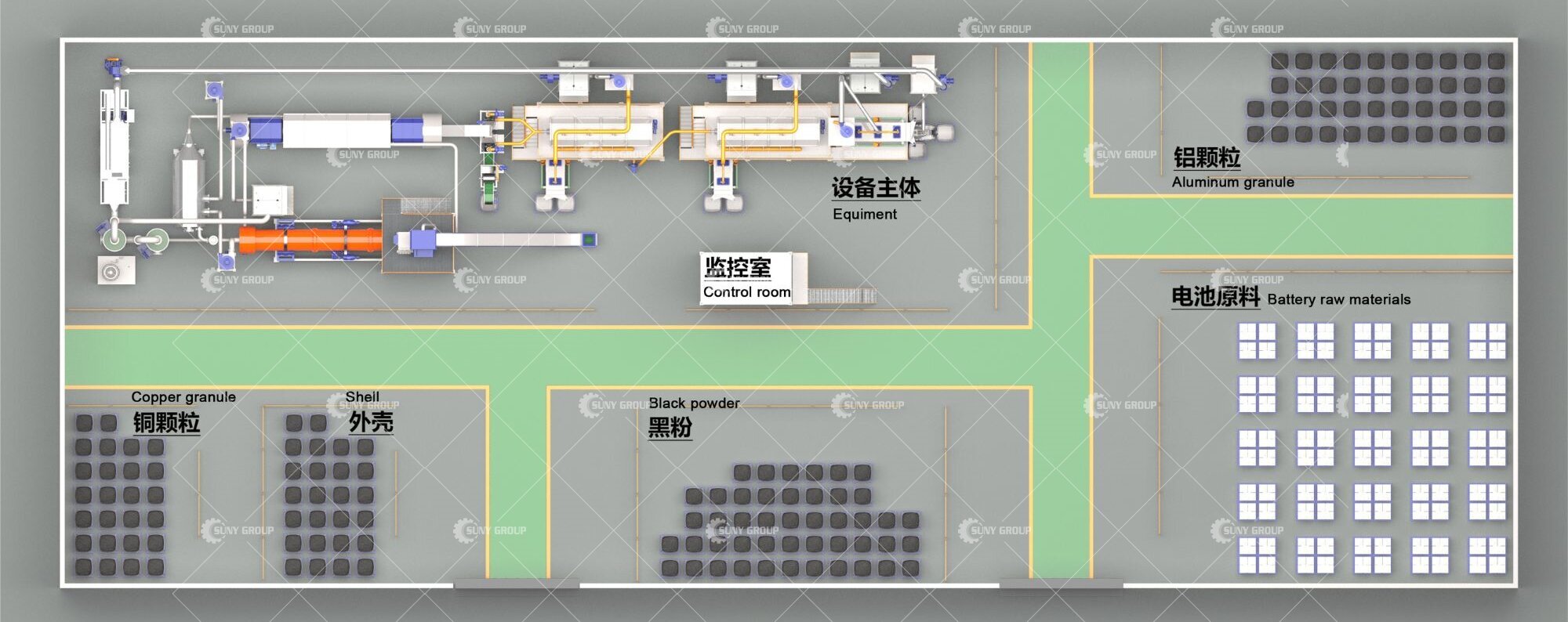

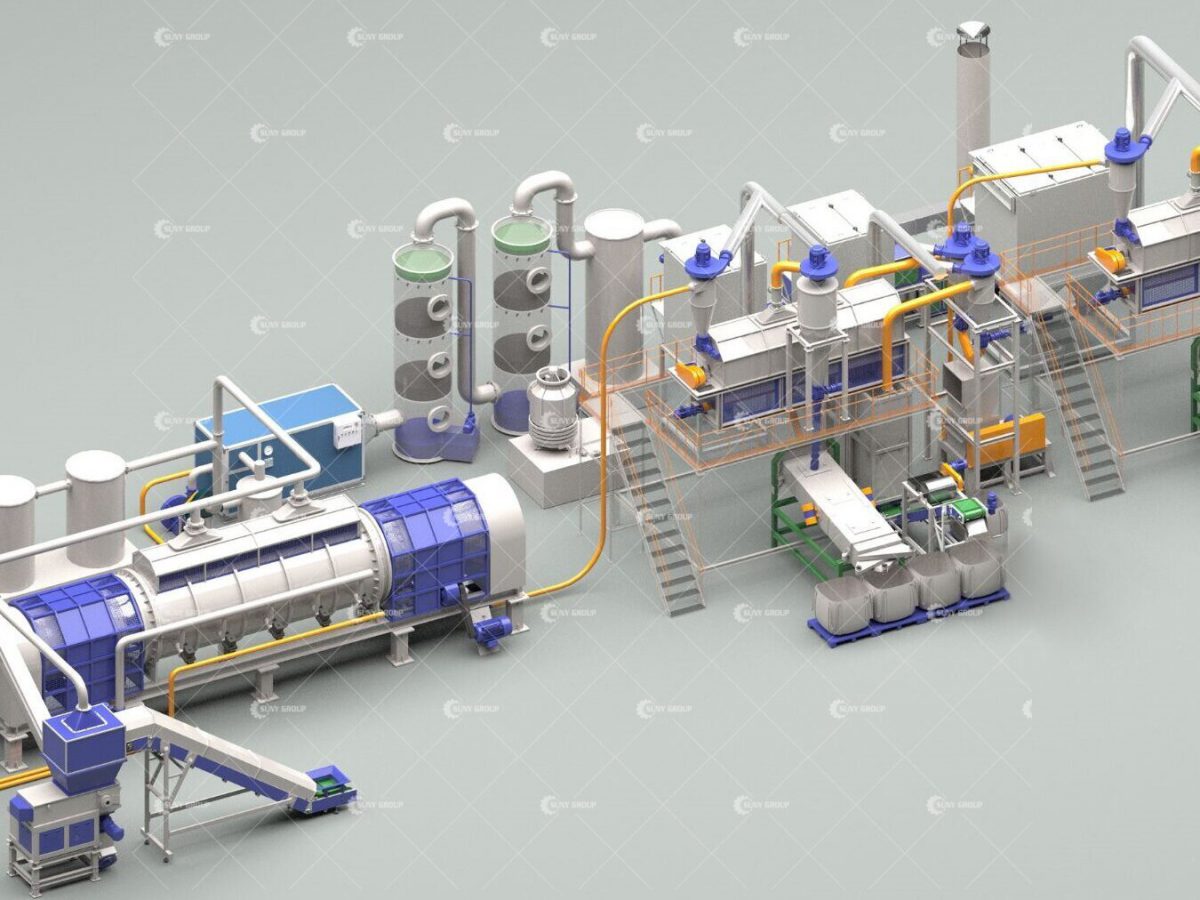

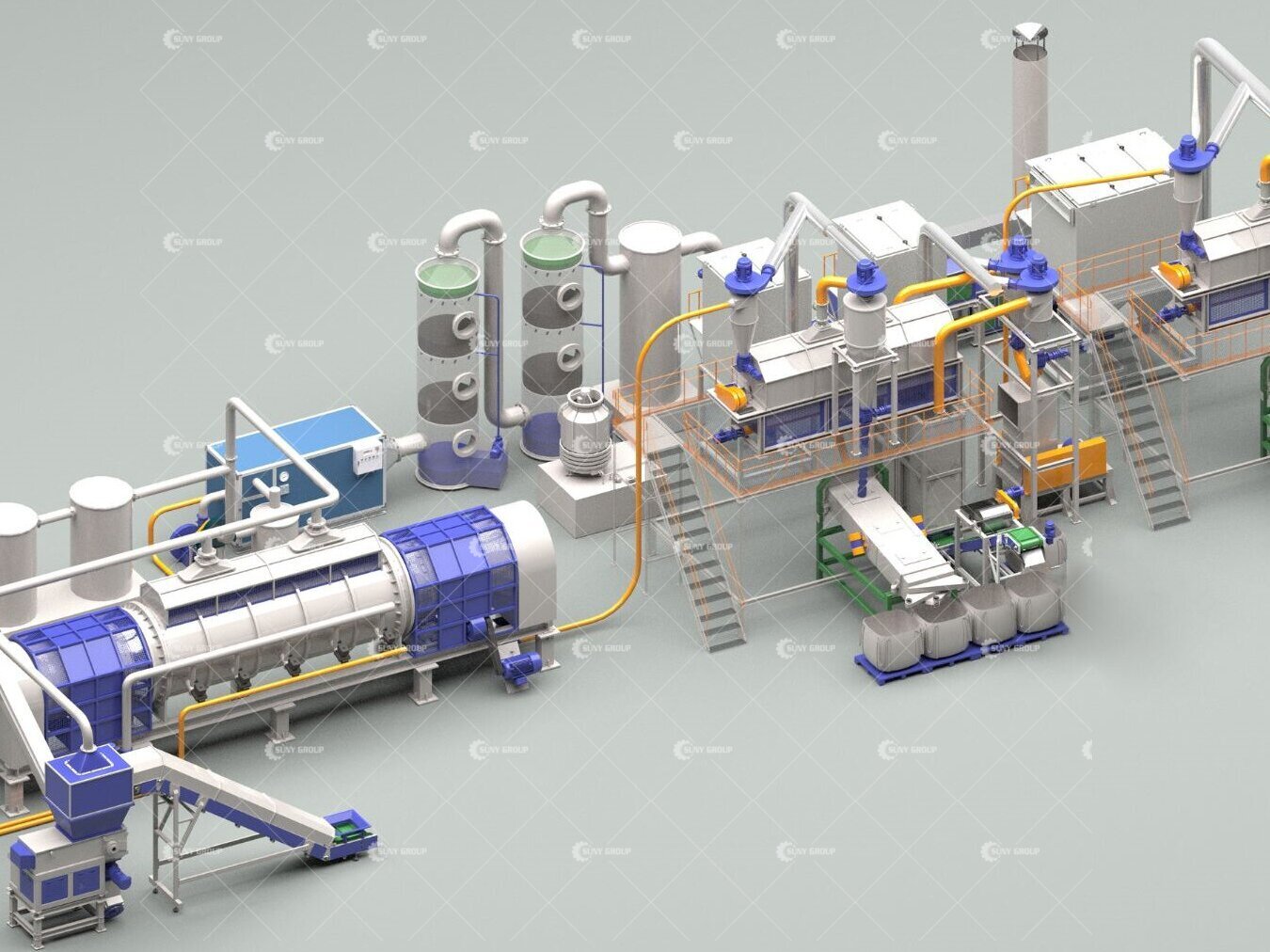

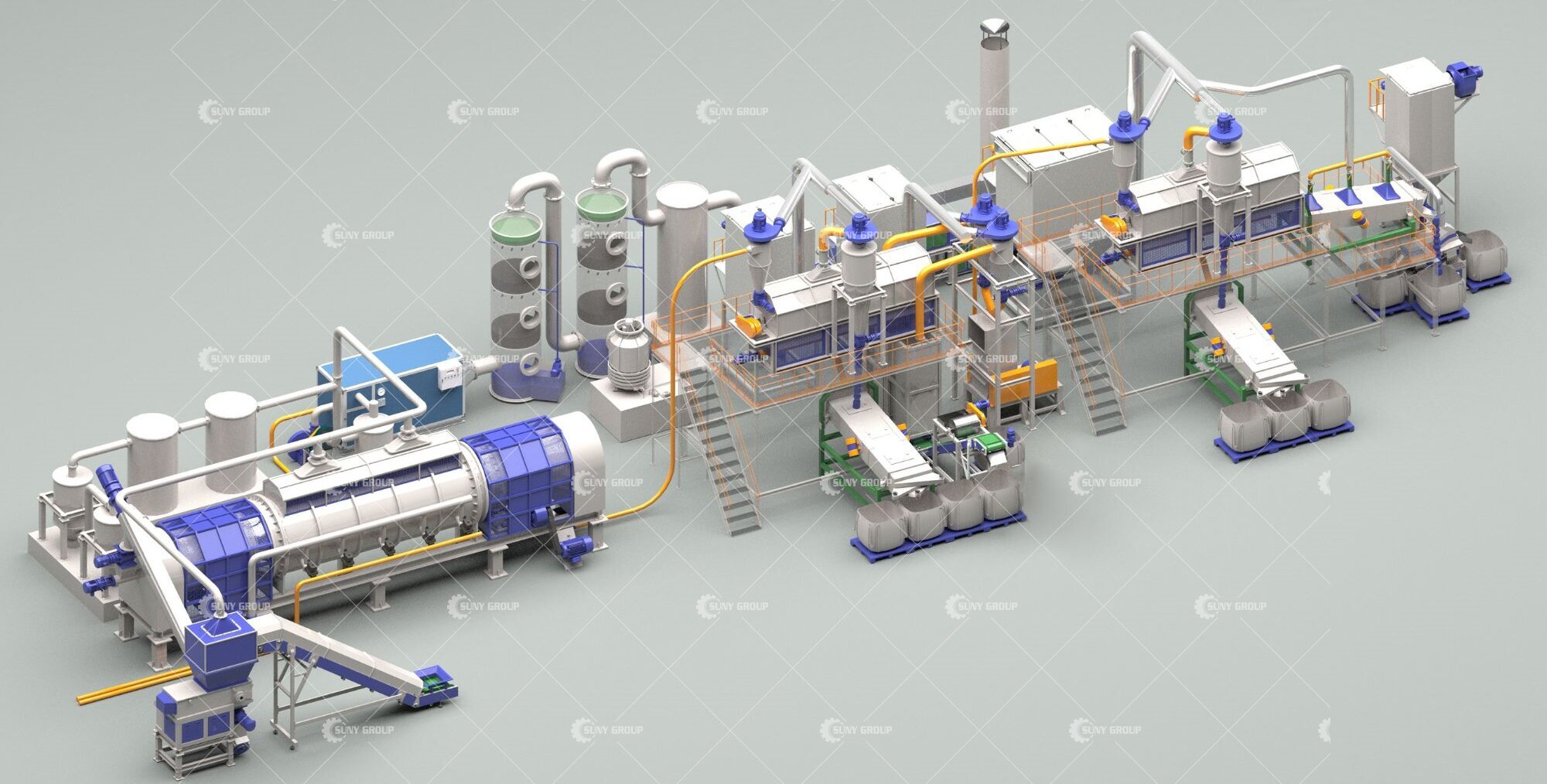

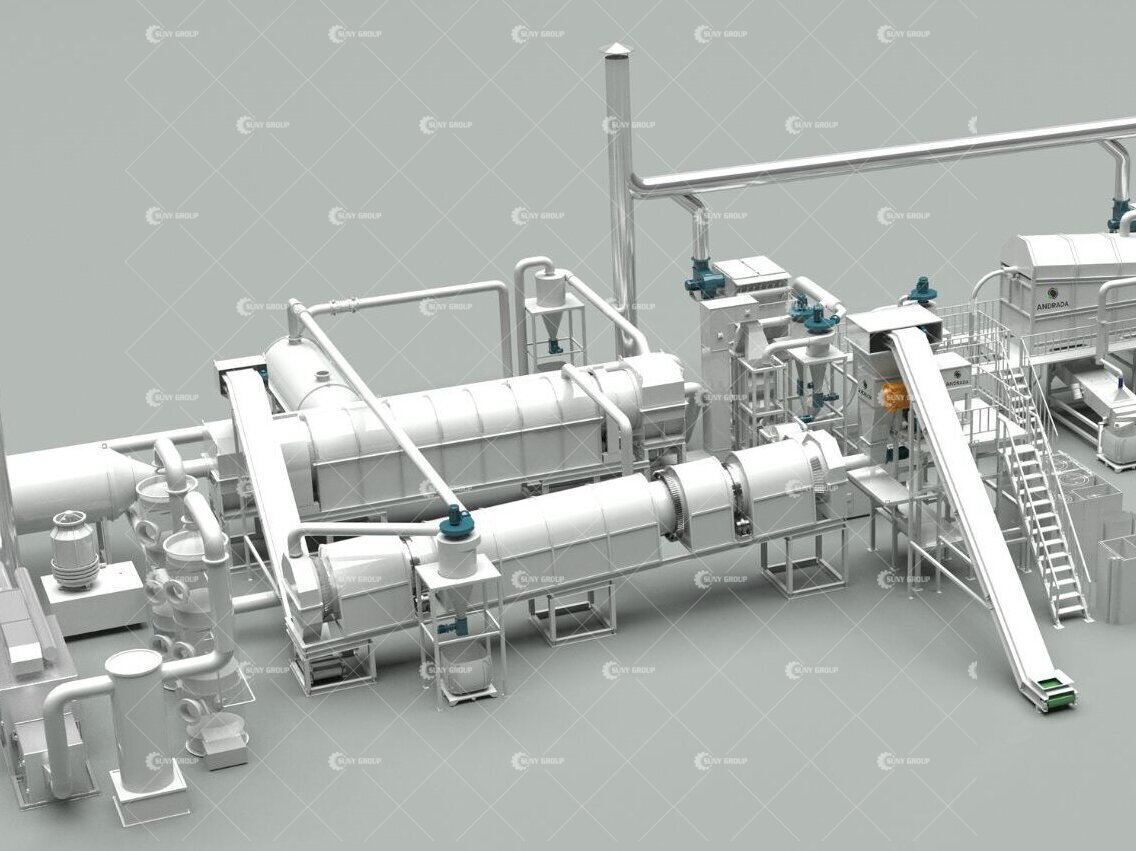

After Mr. Li and his party arrived at our processing workshop, our technical service staff immediately started detailed technical exchanges and discussions. We introduced the working principle, technical features and operating procedures of the lithium battery recycling machine to customers, answered their questions about the operation of the equipment and replacement of accessories, and gave detailed instructions on the purchase and replacement process of accessories.Subsequently, we took customers to visit our processing workshop and demonstrated the manufacturing process and equipment technology of the lithium battery recycling machine. Customers have shown strong interest in our production equipment and processes, carefully observed every link, and asked questions from time to time, expressing their concern for the quality of the equipment and production capacity.

In order to answer customers’ concerns about parts replacement, our technical service staff led Mr. Li and his party to our parts processing workshop. Here, customers witness with their own eyes the manufacturing process and quality control standards of accessories. We introduced the parts processing process and quality inspection standards in detail, allowing customers to have a deeper understanding of the quality and reliability of parts. Through on-site explanations and demonstrations, customers have an intuitive understanding of our technical strength and manufacturing capabilities, and gain confidence in our products. After in-depth discussions and full consideration, Mr. Li and his team decided to purchase our lithium battery recycling machine without hesitation.

Through this on-site visit and exchange, our cooperative relationship with Romanian customers has been further strengthened, and we will continue to work hard to provide customers with better products and services. If you are interested in our products and services or have any questions, please contact our team today.

.png) Product Description

Product Description Model Number:

Model Number:  Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476