Fully Automatic Waste Lithium Ion Battery Recycling Plant Lithium Ion Lead Acid Battery Recycling Machine

.png) Product Description

Product Description Model Number: ZY-500

Model Number: ZY-500 Certification: CE

Certification: CE Warranty: 2 Year

Warranty: 2 Year Voltage: 220V/380V/Customized

Voltage: 220V/380V/Customized

- Detailed Information

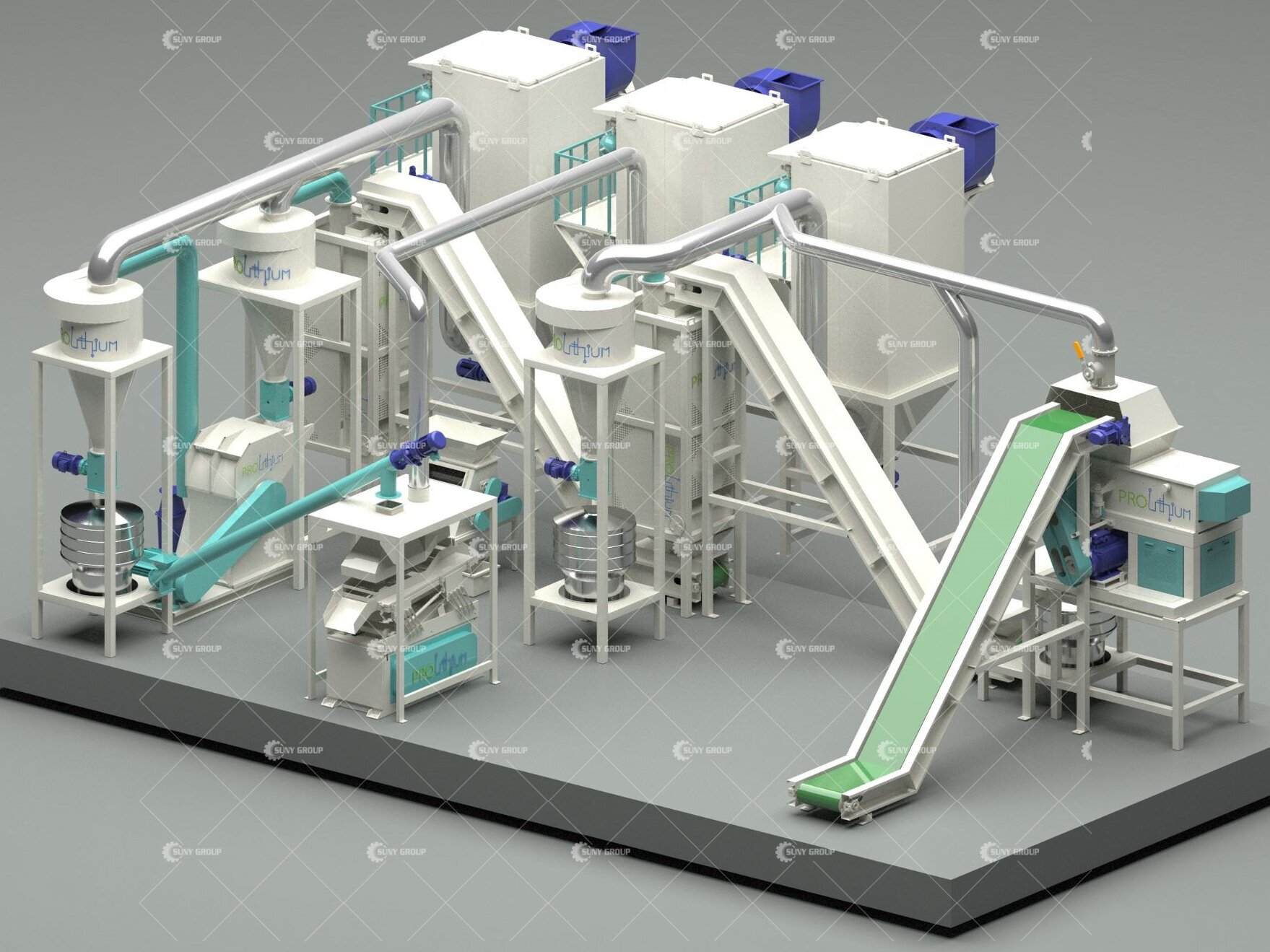

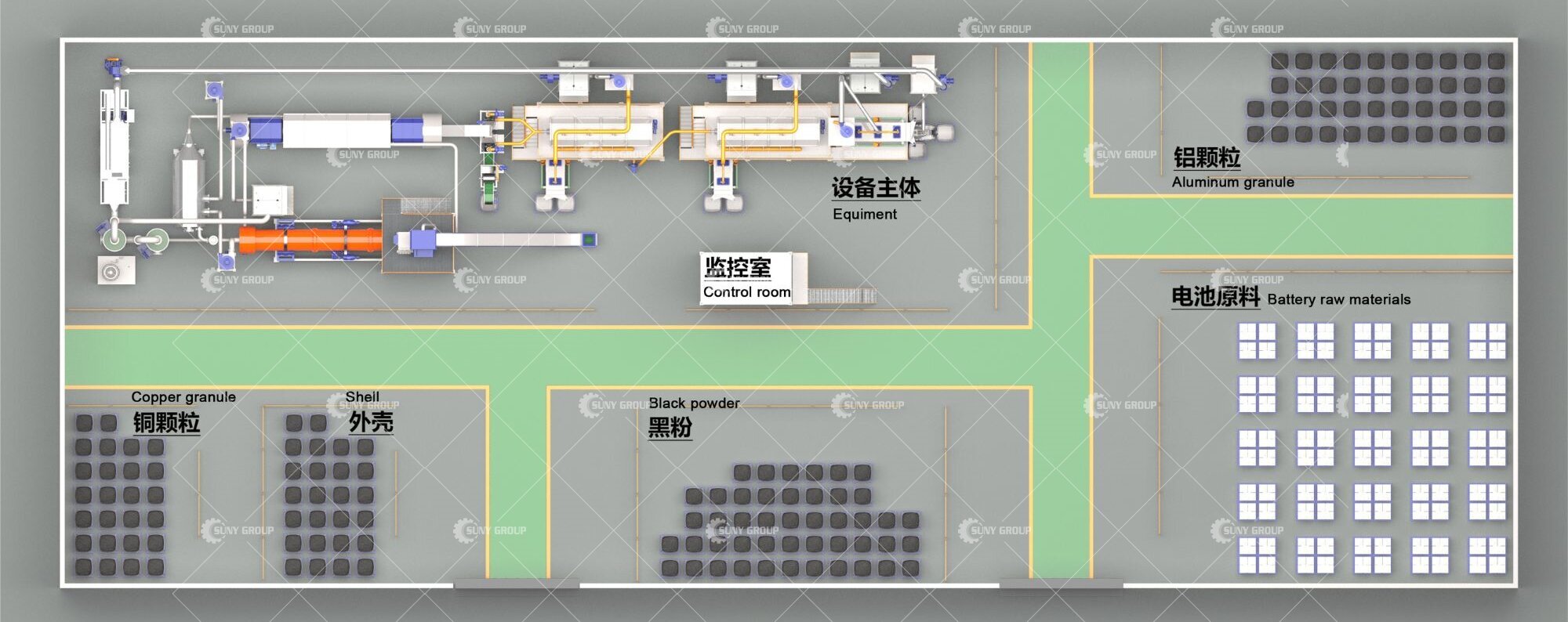

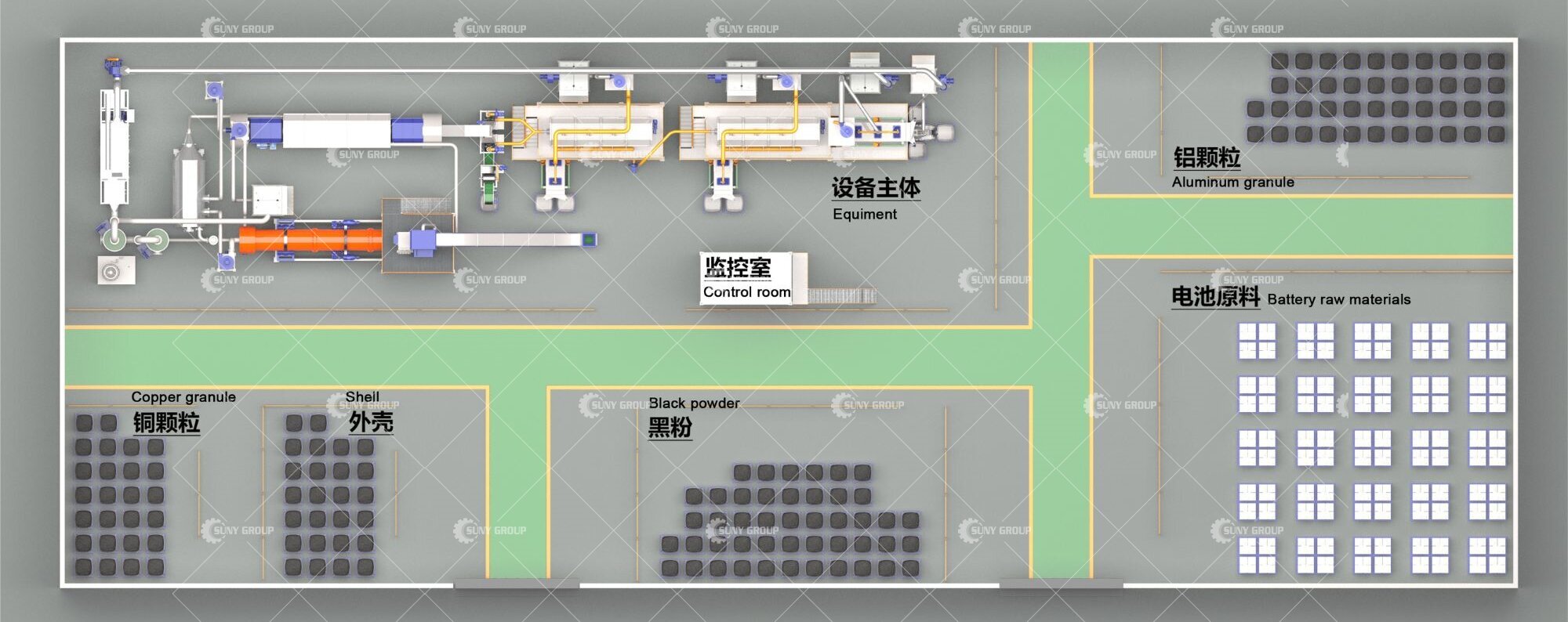

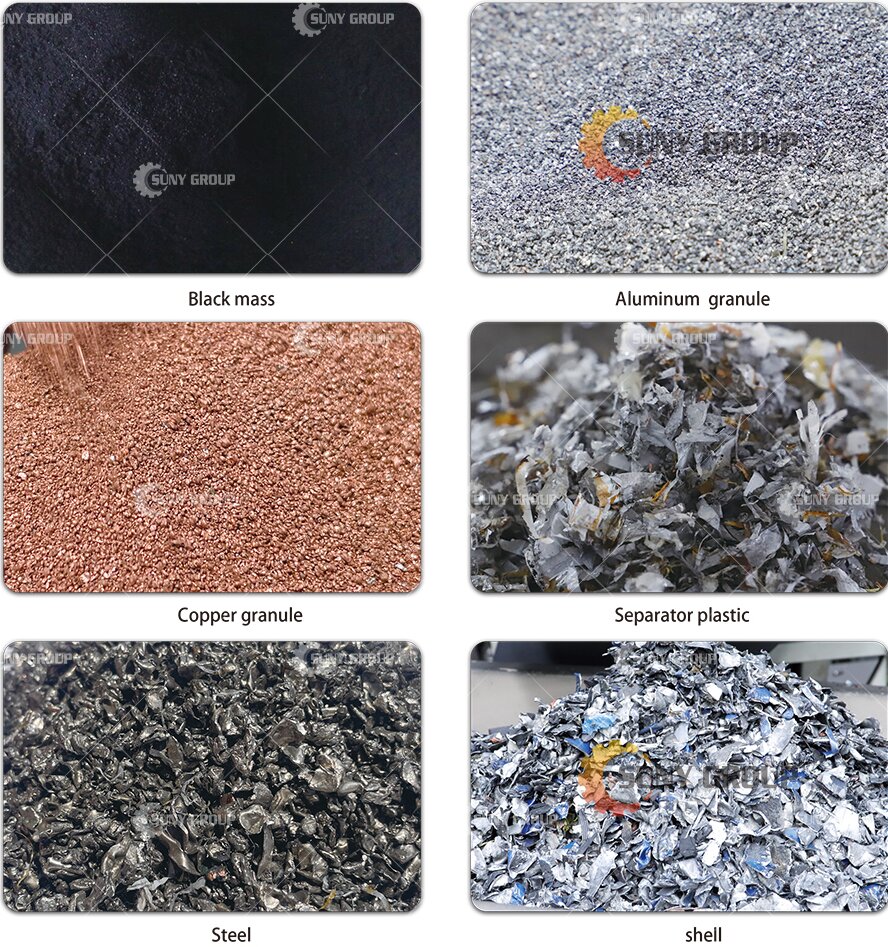

The Lithlum lon Battery Recycling Line is used to recycle Cellphone Battery, Laptop Battery, (EV) CarBattery, Cylindrical Battery, Hard Shell Battery, Li-Polymer – Pouch Type Battery, Automotive Pack andModules Batteries, Positive and Negative Plates etc. The final products are black mass, aluminum granule, copper granule, plastic, steel shell andseparator plastic etc.

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte anddiaphragm. The positive electrode is formed by coating lithium cobaltate powder on two sides ofan aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded toboth sides of the copper foil current collector.

The pretreatment process of Lithium Batetry Recycling Plant mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

| Attributes | Attribute Value |

|---|---|

| Recovery Rate of Metallic Aluminum | >98% |

| Powder Recovery Rate | >98% |

| Content of Powder In Metal Aluminum | <2% |

| Content of Metallic Aluminum In Powder | <2% |

| Qualified Rate | 99% |

| Failure Rate | <1% |

| CMR | ≥1.67 |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Construction works |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Russia, Thailand, Kenya, Argentina, South Korea, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan |

| Place of Origin | Henan, China |

| Final product | Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix Powder |

| Control | PLC+PC+Touch Screen |

| Feature | Easy Operation; High Seperation Rate |

Factory Price Lithium Ion Battery Recycling Machine Waste Battery Recycling Plant

.png) Product Description

Product Description Model Number: ZY-1000

Model Number: ZY-1000 Certification: CE

Certification: CE Warranty: 2 Year

Warranty: 2 Year Voltage: 220V/380V/Customized

Voltage: 220V/380V/Customized

- Detailed Information

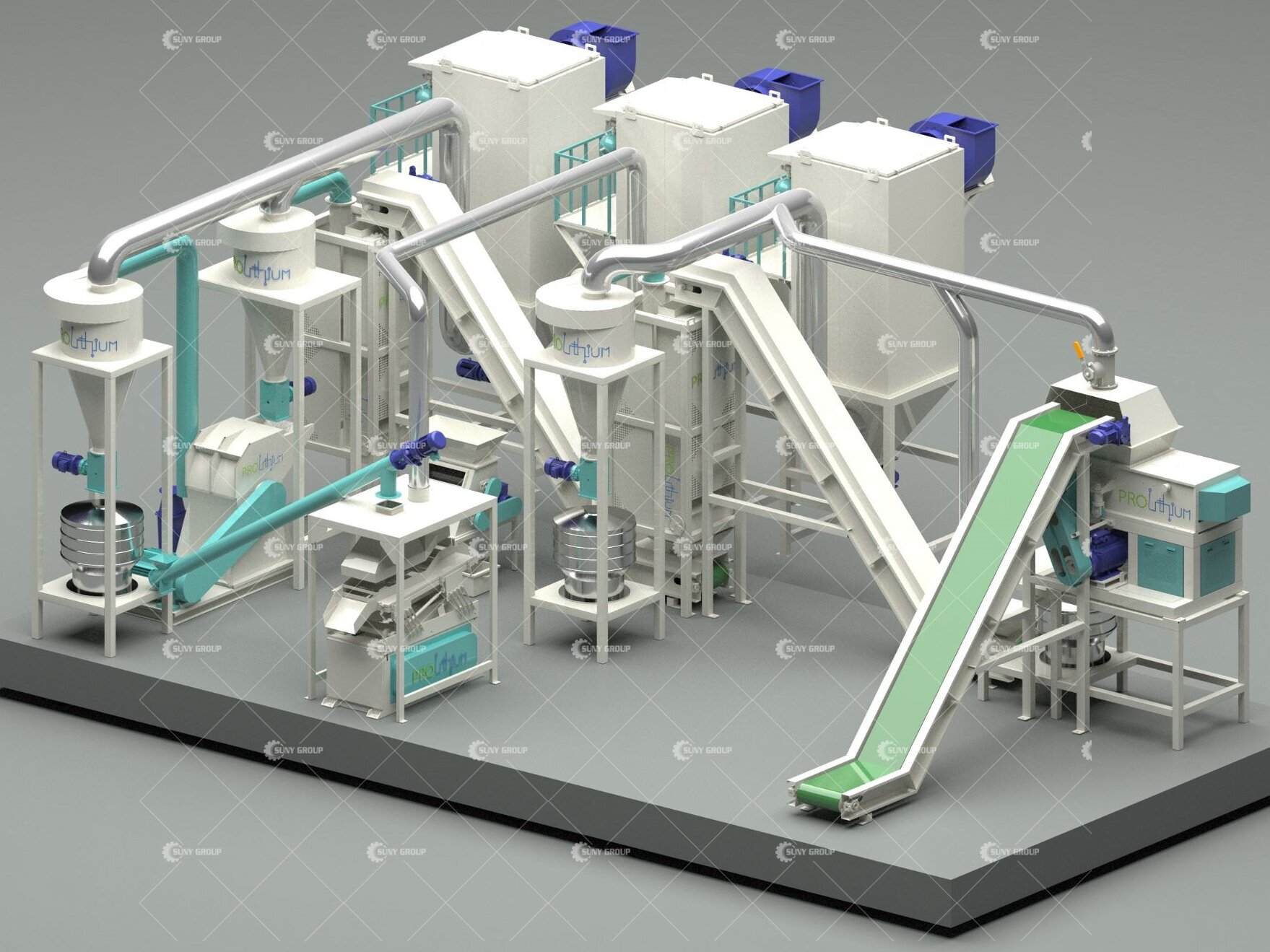

The Lithlum lon Battery Recycling Line is used to recycle Cellphone Battery, Laptop Battery, (EV) CarBattery, Cylindrical Battery, Hard Shell Battery, Li-Polymer – Pouch Type Battery, Automotive Pack andModules Batteries, Positive and Negative Plates etc. The final products are black mass, aluminum granule, copper granule, plastic, steel shell andseparator plastic etc.

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte anddiaphragm. The positive electrode is formed by coating lithium cobaltate powder on two sides ofan aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded toboth sides of the copper foil current collector.

The pretreatment process of Lithium Batetry Recycling Plant mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

| Attributes | Attribute Value |

|---|---|

| Recovery Rate of Metallic Aluminum | >98% |

| Powder Recovery Rate | >98% |

| Content of Powder In Metal Aluminum | <2% |

| Content of Metallic Aluminum In Powder | <2% |

| Qualified Rate | 99% |

| Failure Rate | <1% |

| CMR | ≥1.67 |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Construction works |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Russia, Thailand, Kenya, Argentina, South Korea, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan |

| Place of Origin | Henan, China |

| Final product | Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix Powder |

| Control | PLC+PC+Touch Screen |

| Feature | Easy Operation; High Seperation Rate |

In the pursuit of environmental protection and resource reuse, lithium battery recycling has become the focus of global attention. As a leader in the field of lithium battery recycling, Suny Group has recently launched an innovative process to bring lithium battery recycling to a new level and add another touch of glory to the cause of green environmental protection.

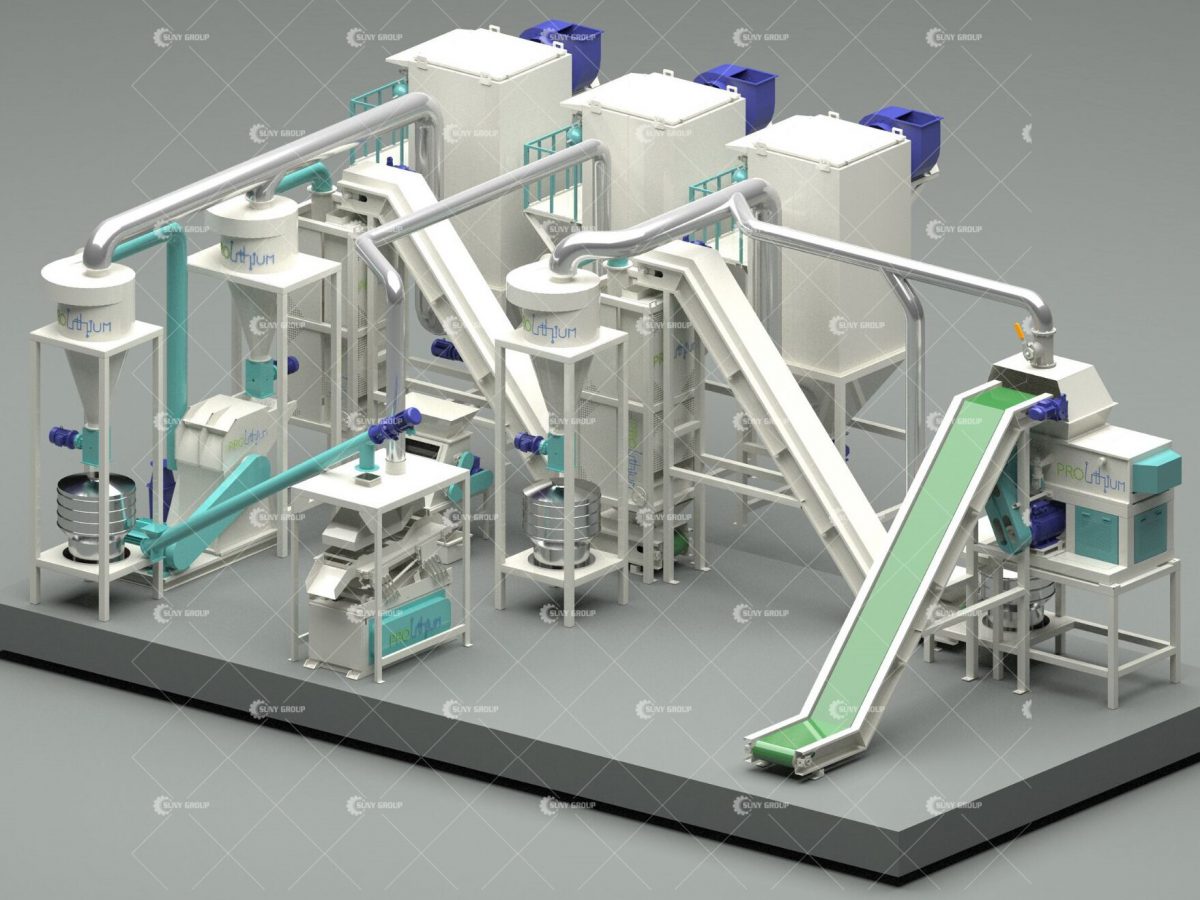

Suny Group’s new process includes the following key steps:

1. Shredder: First, the used lithium batteries are sent to the shredder to be shredded into small pieces.

2. Hammer crusher: Next, the shredded materials are sent to the hammer crusher for secondary crushing and separation to further refine the materials.

3. Crusher: The crushed materials are sent to the pulverizer for crushing treatment to achieve a finer particle size.

4. Separator: The crushed materials are separated by wind through the analysis machine to separate valuable metal elements from other materials.

5. Collector: The separated metal elements are collected and discharged through the induced draft fan to ensure resource reuse and environmental protection.

6. Pulse purifier: The dust in the entire equipment is purified by the pulse purifier to ensure a clean production environment.

7. Classification screen: The materials sorted by the analysis machine are sent to the classification screen for screening, and large metal materials are sorted out.

8. Magnetic separator: The magnetic separator separates the nickel from the metal and provides pure metal materials for subsequent processing.

9. Specific gravity sorting machine: The fine materials that have been sorted and screened are then sorted by specific gravity to completely separate metals and other materials.

10. High-pressure fan: The entire system is in a negative pressure state, collecting powder and purifying the air to ensure a clean production environment and employee health.

This innovative process not only improves the efficiency and quality of lithium battery recycling, but also greatly reduces environmental pollution and achieves sustainable use of resources. In Suny Group’s process, the main materials recovered from used lithium batteries include: Black mass, Aluminum granule, Copper granule, Separator plastic, Steel, and shell.

Our team sincerely welcomes customers from all over the world to contact us. We will provide you with the most satisfactory solutions with professional technology and services. Contact us now and let us work together to create a broader future for lithium battery recycling!

The United States, the cradle of scientific and technological innovation, is also a hot spot for the rapid development of the environmental protection industry. Recently, we were fortunate to welcome an important customer from the United States. He decided to seek new technical equipment amid the rapid development and fierce competition faced by the same industry. By participating in the lithium battery recycling exhibition, he saw the capabilities of our factory. Due to our technical strength, we decided to come to our production factory in person to participate in the trial operation of our new machines off the assembly line. During this special visit and exchange, our team accompanied us throughout the entire process, demonstrating our professional technology and excellent quality to our customers.

This customer from the United States is facing the challenges of rapid development and fierce competition in the same industry. Therefore, it is urgent to introduce new technical equipment to enhance its competitiveness in the field of lithium battery recycling. By participating in the lithium battery recycling exhibition, he had a preliminary understanding of the technical strength of our factory, and decided to come to our production factory in person to participate in the trial operation of our new machines to gain an in-depth understanding of our technical solutions and product performance.

In communicating with customers, we learned that customers have high expectations for our equipment performance and technical solutions. In order to meet the needs of customers, we have made sufficient preparations in advance to ensure that we can provide customers with professional technical support and full service guarantee. After the customer arrived at our company, we arranged a full trial operation. We introduced the technical features and operating procedures of our new machine to our customers, and then conducted an on-site trial run. The customer personally participated in the trial operation and experienced the performance and stability of the equipment. Through on-site communication and experience, customers have a deeper understanding of our technical solutions and product performance.

During the trial operation, the customer expressed high recognition and trust in our machine quality and technical patents, and decided to sign a long-term purchase contract with us. The customer said that by introducing our advanced equipment, it will help them obtain more local lithium battery recycling resources and improve their competitiveness and market share. No matter what challenge or need you face, our team is here to serve you. Contact us now and let us start the journey of lithium battery recycling cooperation and achieve your goals together.

Thailand, this exotic country, is the pearl of Southeast Asia and a region where the environmental protection industry is developing rapidly. Recently, we were fortunate to welcome important customers from Thailand. They showed strong interest in lithium battery recycling equipment and learned about the quality of our equipment and stable after-sales service through other recyclers, so they came here specially. Our company visited our production workshop on site. During this special inspection and exchange, our team accompanied us throughout the entire process, demonstrating our professional skills and excellent quality to our customers.

This customer from Thailand represents a company with a good reputation in the environmental protection industry. They are very concerned about the performance and effect of lithium battery recycling equipment. By understanding our equipment quality and service advantages, they hope to establish a long-term and stable cooperative relationship with us, introduce advanced equipment technology, and enhance the company’s competitiveness in the field of environmental protection.

In communicating with customers, we learned that customers have high expectations for our equipment performance and after-sales service. Therefore, we have made sufficient preparations in advance to ensure that we can fully demonstrate our production process and equipment performance to customers, as well as our commitment and guarantee in after-sales service.After the customer arrived at our company, we arranged a full visit and communication activities. We first introduced our company’s production process and equipment technology to customers, and explained in detail the working principle, operating procedures and technical characteristics of the equipment. Through on-site demonstrations and illustrated explanations, customers have a comprehensive understanding of our production processes and equipment performance.

During the visit, we focused on demonstrating the performance and effects of our lithium battery recycling machine equipment. Through physical displays and on-site demonstrations, we showed customers the crushing, separation and recycling process of the equipment, allowing them to witness the working efficiency and stability of the equipment with their own eyes. Customers expressed high satisfaction with the performance of the equipment and fully affirmed our technical level and production capabilities.

Lithium-ion batteries have become ubiquitous in modern life, powering everything from smartphones and laptops to electric vehicles and grid-scale energy storage systems. However, like all batteries, lithium-ion batteries have a limited lifespan and will eventually need to be replaced. This brings up the problem of recycling. How to recycle lithium batteries? In this article, we will discuss what lithium-ion batteries are and their recycling process.

Lithium-ion batteries are rechargeable batteries that use lithium ions as the main active material. These batteries have higher energy density than other types of batteries, such as lead-acid or nickel-metal hydride, and offer several advantages. Lithium-ion batteries consist of an anode, cathode, separator and electrolyte. The anode is usually made of graphite, the cathode is made of metal oxide, and the separator is a polymer film that prevents the electrodes from touching each other. An electrolyte is a liquid or gel that allows ions to move between electrodes.

Lithium-ion batteries can be recycled to recover valuable materials and reduce the environmental impact of disposal. The first step in recycling lithium-ion batteries is collection. Lithium-ion batteries can be harvested from a variety of sources, including consumer electronics, electric vehicles and energy storage systems. Collection can be done through municipal recycling schemes, waste collection points or mail-in schemes. Lithium-ion batteries must be handled carefully during collection to prevent damage or short circuits. Mechanical crushing is a process that involves the use of crushers and grinders to break batteries into small pieces. The resulting material is then separated into different fractions using sieves and magnetic separators. This process is typically used in batteries containing high proportions of valuable metals such as cobalt, nickel and copper. In addition to these metals, there is also Battery Carbon Black. Battery Carbon Black is a blend of ingredients such as lithium, cobalt, nickel, manganese, copper and aluminum. It also contains graphite and other non-metallic elements such as plastics, electrolytes and adhesives. Battery Carbon Black is typically a fine black powder that requires further processing to separate and recover the valuable metal.

Through the above processes and methods, lithium battery recycling can not only effectively reduce environmental pollution, but also realize the reuse of resources and make a positive contribution to sustainable development. Suny Group will continue to uphold the concept of green environmental protection, continue to innovate, and inject new impetus into the global environmental protection cause.Our team warmly welcomes customers from all over the world to contact us. We will provide you with customized solutions to meet your needs with a professional attitude and rich experience.

In the tide of international trade, the intimate relationship between partners is not only based on product quality and service level, but also incorporates recognition of each other’s strength and trust. Recently, our factory welcomed an important customer from Turkey. He represents a company dedicated to the lithium battery environmental recycling industry. With a strong interest in lithium battery recycling technology, he came to our factory for an on-site visit and exchange. . Lithium battery recycling provides necessary raw materials for manufacturing new batteries, while reducing reliance on limited resources and promoting sustainable development. Lithium batteries contain a variety of valuable materials that are worthy of recycling, including: lithium, cobalt, nickel, aluminum, manganese, copper, plastic and other components.

This customer from Turkey represents a company in the emerging environmental protection industry. He has a strong interest and potential business opportunities in the field of lithium battery recycling. He hopes to enhance the company’s competitiveness in the environmental protection field by introducing advanced lithium battery recycling equipment and make greater contributions to the development of Turkey’s local environmental protection industry.

After the customer arrived at our company, we arranged a full visit and communication activities. We introduced the working principle, technical features and operating procedures of lithium battery recycling equipment to our customers. At the same time, we also introduced the importance of lithium battery recycling to customers, including information on providing necessary raw materials for manufacturing new batteries, reducing dependence on limited resources, and promoting sustainable development. During the visit, we focused on demonstrating the performance and effects of our lithium battery recycling machine equipment. We showed the customer the crushing, separation and recycling process of the equipment, allowing him to witness the working efficiency and stability of the equipment with his own eyes. Customers expressed high satisfaction with the performance of the equipment and fully affirmed our technical level and production capabilities.

During the visit and exchange, we had in-depth exchanges and discussions with our customers on the technical details of the equipment and commercial cooperation. The customer showed strong interest in the performance and technical indicators of the equipment and expressed his willingness to establish a long-term and stable cooperative relationship with us. The two parties reached a preliminary consensus on equipment procurement, technical support and cooperation models, and determined specific plans and timetables for the next step of cooperation.

During this inspection and exchange, our professional team accompanied us throughout the entire process and introduced our production process, technical features and equipment performance to customers, in order to provide customers with satisfactory solutions. Our team will wholeheartedly provide you with the highest quality products and services with integrity, professionalism and responsibility. If you are interested in our products or have any questions, please contact our team today.

International trade between China and Russia has flourished under the construction and operation of the Silk Road, injecting new vitality into the economic cooperation between the two countries. Not long ago, our factory welcomed two important guests from Russia. They came to our equipment production workshop with their needs and questions about lithium battery recycling equipment. During this inspection and exchange, our professional and technical personnel accompanied the entire process and answered the customers’ technical questions in detail, including the machine’s operating process, crushing stage, separation stage, recycling stage, exhaust gas dust treatment system, and recycling principles.

Considering China’s leading position in the field of environmental protection equipment manufacturing, they chose to visit our company, hoping to find high-quality equipment that suits their company’s needs. After the guests arrive at our company, we arrange a full visit and exchange activities. First, our technicians introduced the working principle, technical features and operating procedures of lithium battery recycling equipment to the guests. Through physical displays and explanations with pictures and texts, we allowed guests to have an intuitive understanding of the structure and working principle of the equipment, and answered various technical questions raised by guests in detail.

During the visit, we focused on the operation process of the equipment, including the crushing stage, separation stage and recycling stage. Through on-site demonstrations, we demonstrated the stability and efficiency of the equipment, allowing guests to have an intuitive feel for the working effect of the equipment.

In view of environmental protection issues, we also introduced the equipment’s exhaust dust treatment system to our guests. We explained in detail how the equipment handles exhaust gas and dust, and demonstrated our advanced exhaust gas treatment equipment to give guests a deeper understanding of our environmental protection measures. Finally, we also introduced the principles of equipment recycling to guests, including recycling methods and technologies for various elements of lithium batteries. We explained in detail the technical points and precautions in the recycling process, allowing guests to have a deeper understanding of the recycling efficiency and technical level of the equipment.

Through this inspection and exchange, the two guests had a comprehensive understanding of Suny Group’s lithium battery recycling equipment, and showed a high degree of recognition of Suny Group’s technical strength and production capabilities. Thank you to our customers for their support and trust in us. At the same time, we also warmly welcome customers from all over the world to contact us to jointly explore and exchange lithium battery recycling technology.

Email:zyunfei87@gmail.com

Email:zyunfei87@gmail.com WhatsApp:+86 19903886476

WhatsApp:+86 19903886476