Online WhatsApp:

+86-19903886476Online WhatsApp:

+86-19903886476In recent years, with the increasing impact of battery waste treatment on the environment, the recycling technology of waste lead-acid batteries has developed rapidly. The final disposal methods of batteries are mainly landfill, incineration and recycling. In order to reduce the harm of waste batteries to the environment, the lead ingot smelting cup furnace waste car battery recycling technology came into being and became an important breakthrough in the environmental protection industry.

According to 500 questionnaire surveys conducted in Zhengzhou, Jiaozuo and Dengcheng, Henan Province, 39.24% of the public discarded batteries at will, 17.72% of people did not know how to deal with them because there were no waste battery recycling stations, 38.38% of people put batteries in ordinary trash cans, and only 12.66% of people put waste batteries in special recycling stations. These data show that even at the source, the recycling rate of used batteries is very low, not to mention a higher reuse rate. Therefore, research on the recycling and reuse of used batteries has become increasingly necessary.The lead ingot smelting cup furnace is a melting device used to melt metals such as cast iron, copper, and lead. Its structure is cylindrical, the equipment is arranged vertically, and it is usually supported by four legs. It looks like a large chimney. The bottom of the cup furnace is equipped with a door that swings down and outward for dumping waste. The top can be open or a cover can be installed to prevent rainwater from entering. In order to control emissions, the cup furnace may be equipped with a cover for introducing gas into the equipment to cool and remove particulate matter.

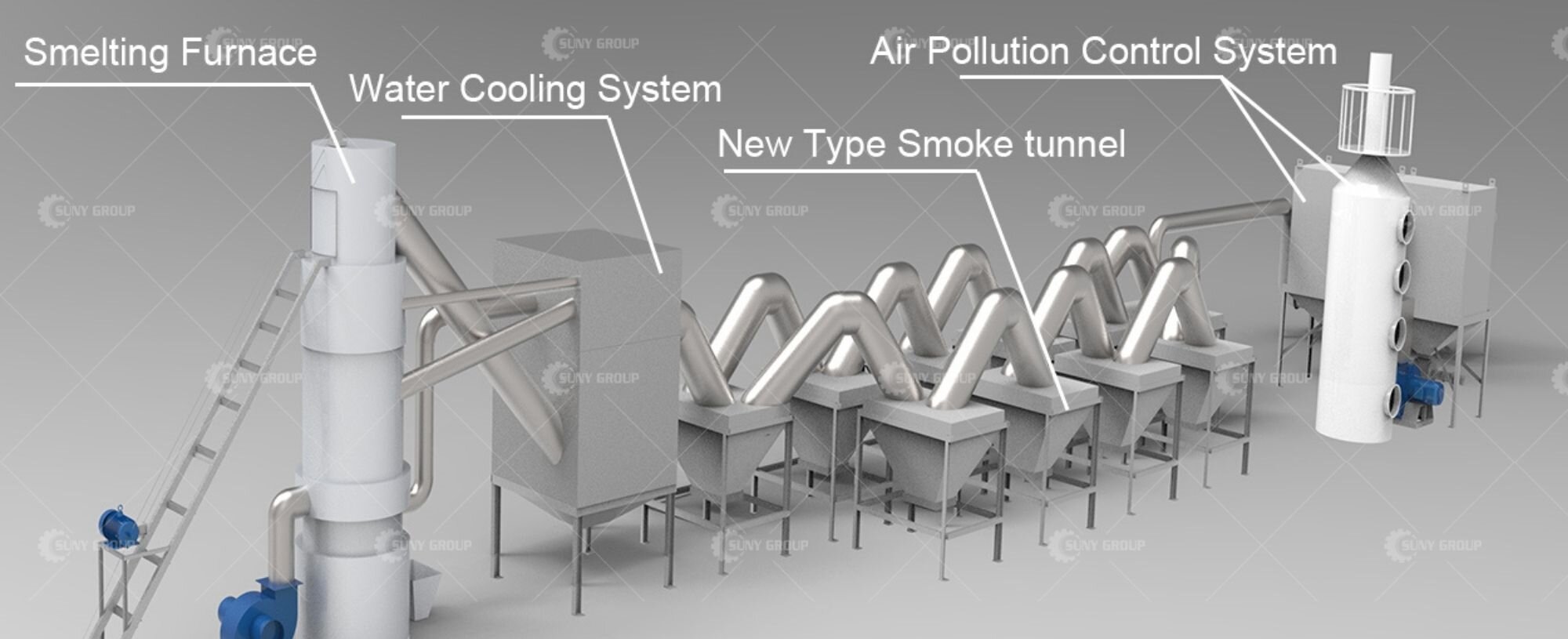

The entire production line of the lead ingot smelting cup furnace for recycling used automotive batteries focuses on environmental protection. First, the used lead-acid batteries will be separated by a “battery separator”, and the separated final products include plastics, lead, and acid. The crude lead can be refined through the smelting section, and if deep recycling is required, a cup furnace can be selected to obtain refined lead ingots. The smelting section is also equipped with an air pollution purification system to meet the requirements of environmental protection policies.

Lead ingot smelting cup furnace for recycling used automobile batteries not only has significant advantages in environmental protection, but also has significant economic benefits. Through efficient automated production processes, labor costs are reduced and production efficiency is improved.

Inquiry Form