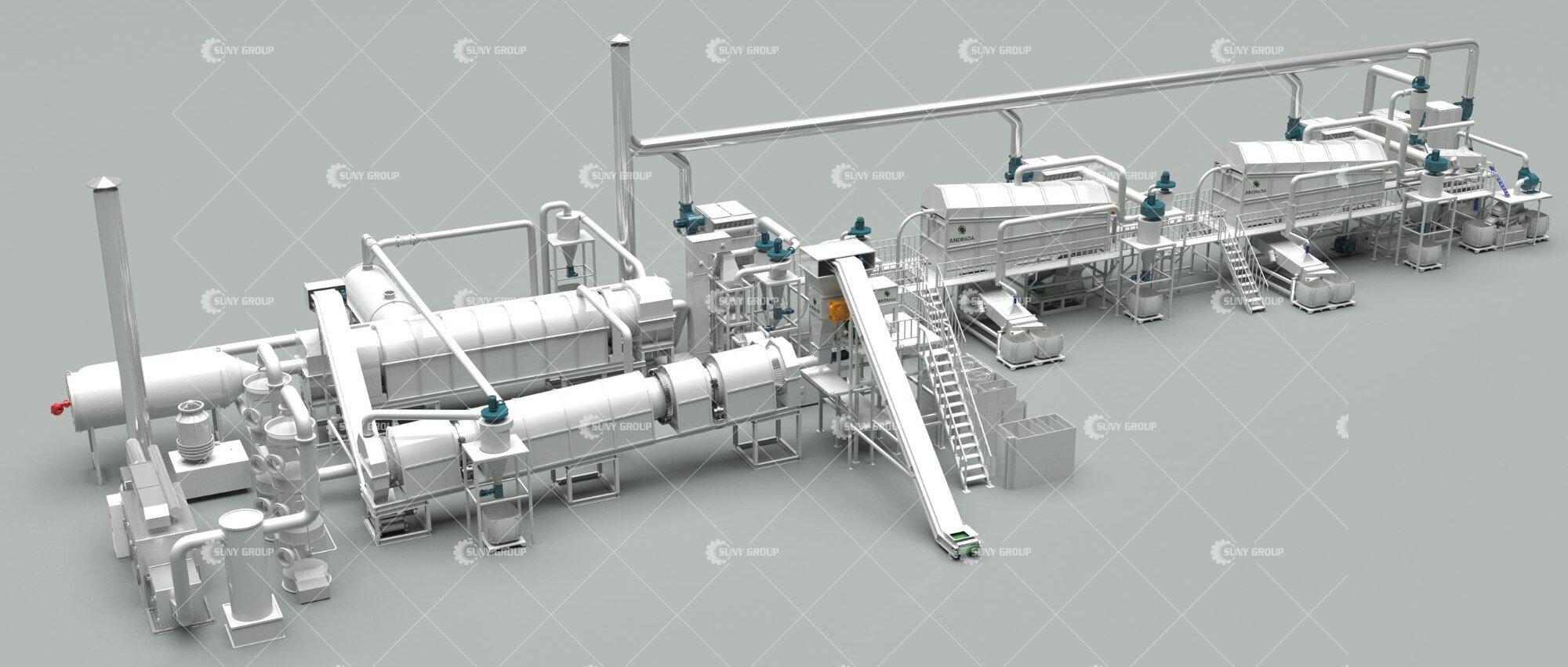

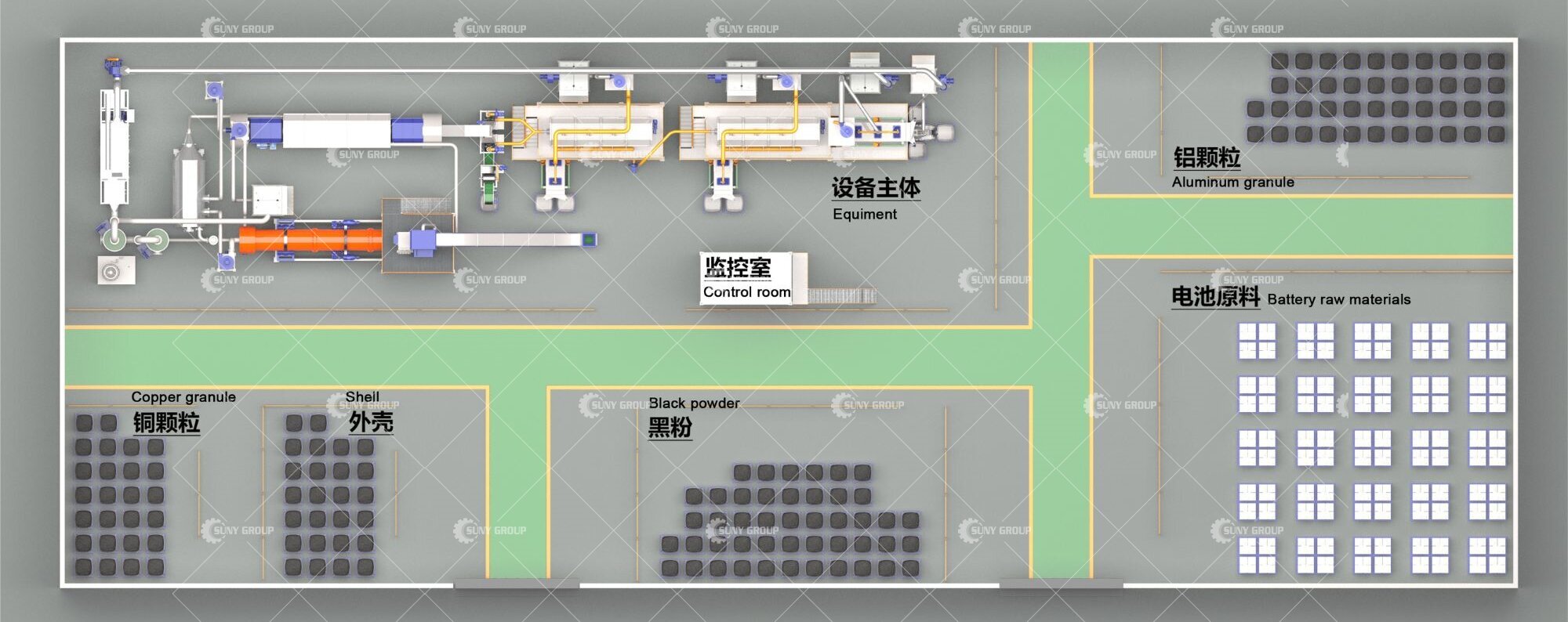

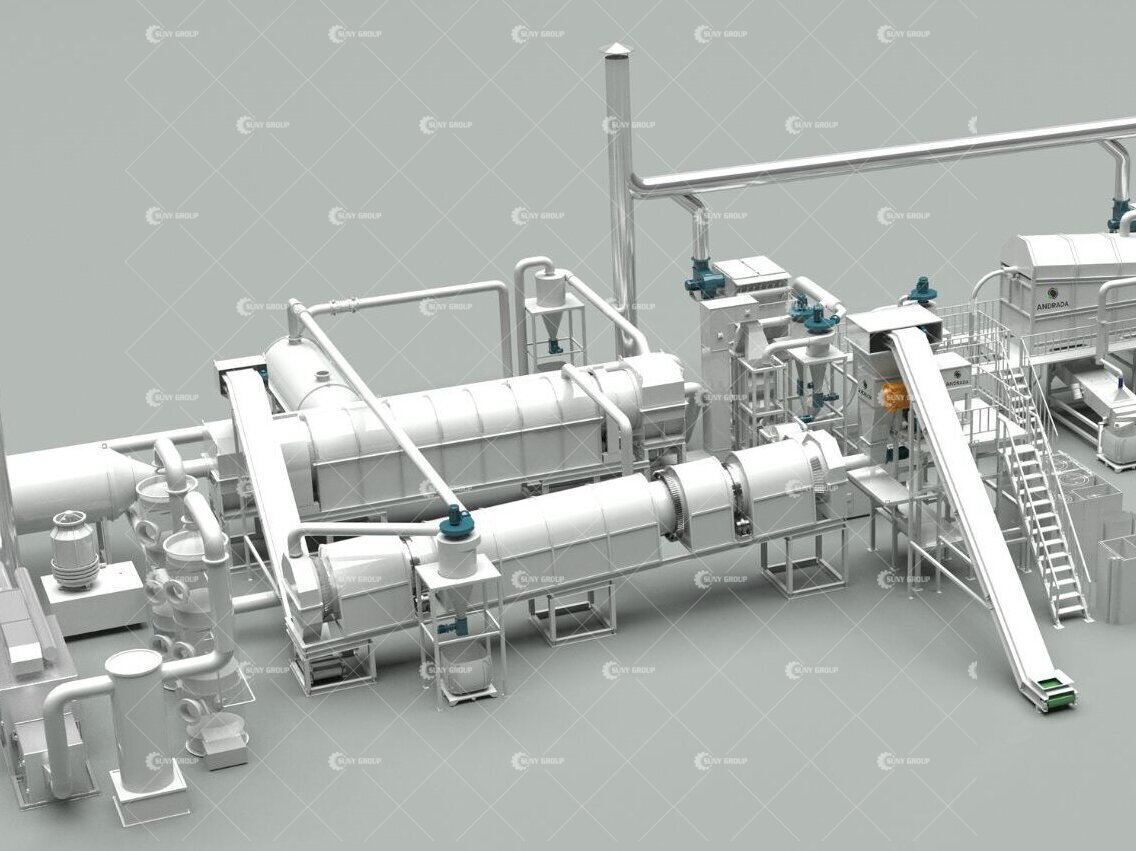

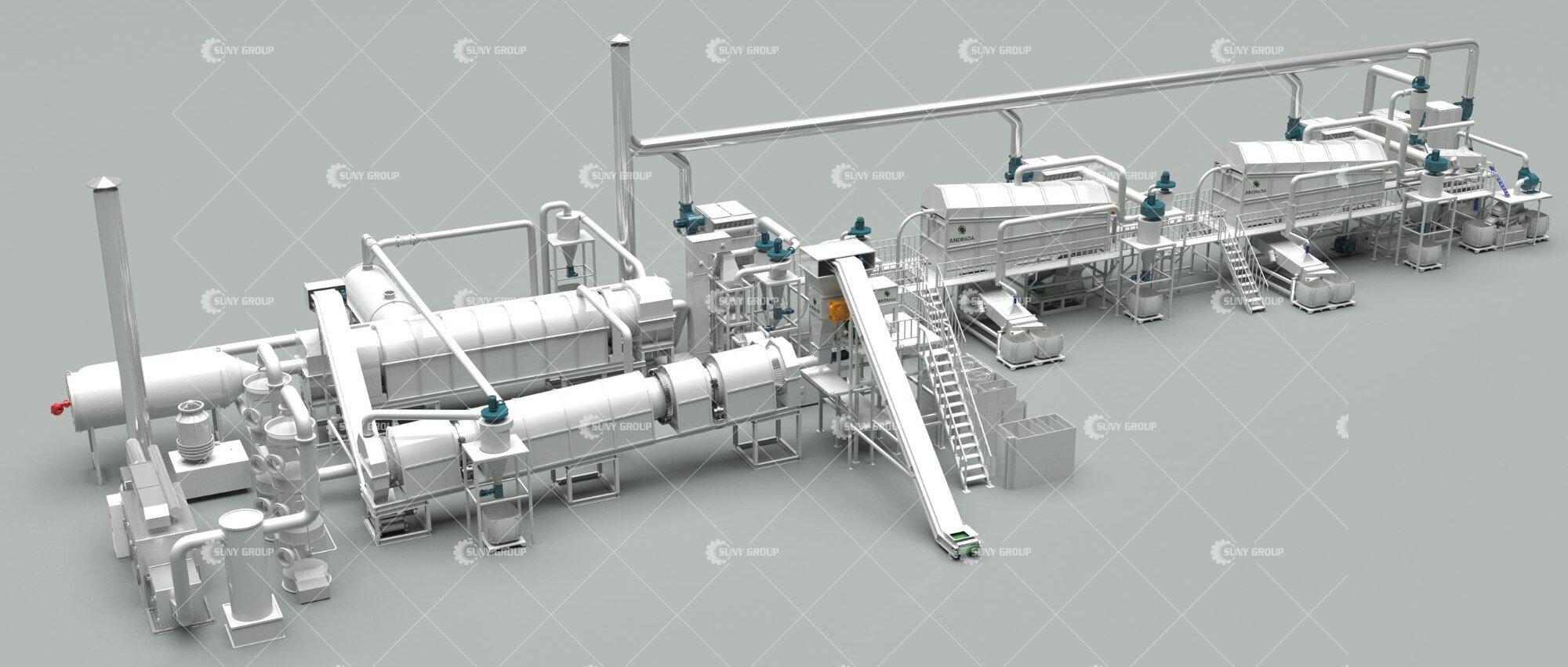

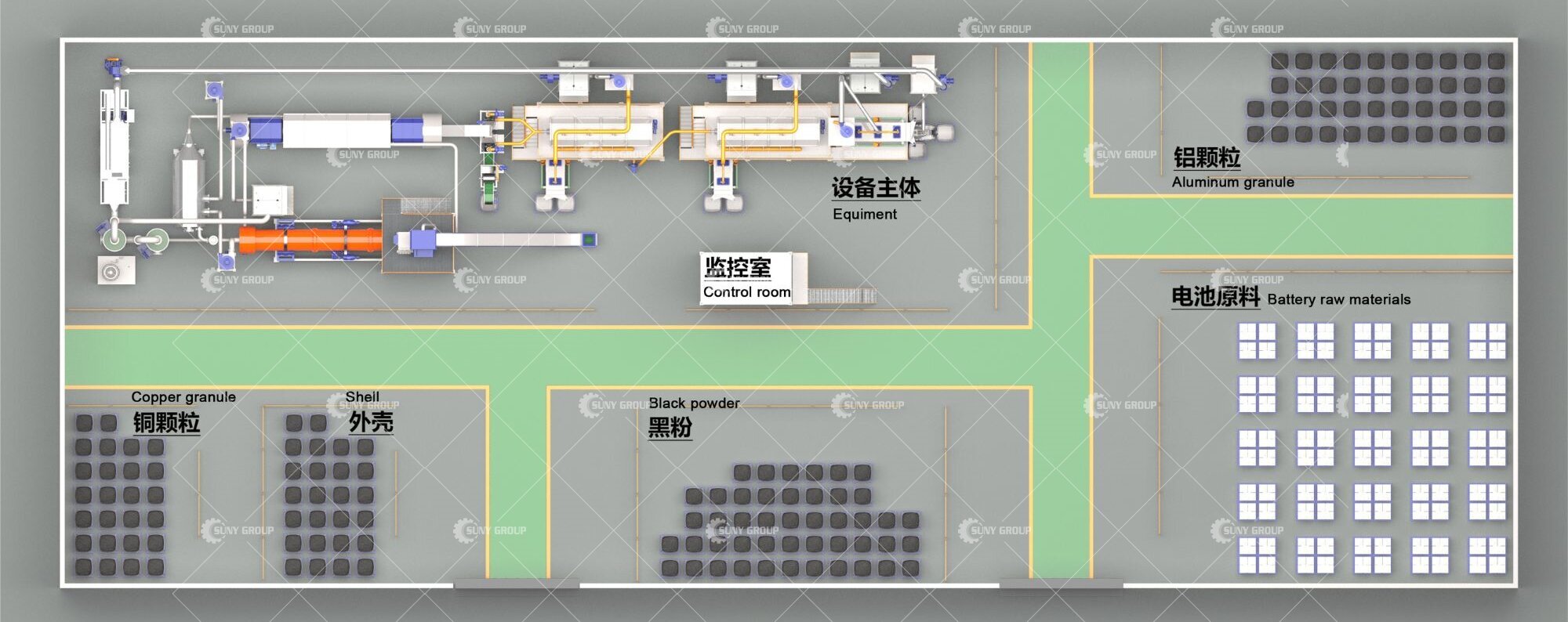

Any company can use the lithium ion battery recycling machine to recycle 1500 kg of lithium ion materials per hour to any desired saleable state. Through mechanical equipment for crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes, the powder on the positive and negative plates is effectively separated from the copper and aluminum foil, and the battery is processed as a valuable material.

The Lithlum lon Battery Recycling Line is used to recycle Cellphone Battery, Laptop Battery, (EV) CarBattery, Cylindrical Battery, Hard Shell Battery, Li-Polymer – Pouch Type Battery, Automotive Pack andModules Batteries, Positive and Negative Plates etc. The final products are black mass, aluminum granule, copper granule, plastic, steel shell andseparator plastic etc.

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte anddiaphragm. The positive electrode is formed by coating lithium cobaltate powder on two sides ofan aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded toboth sides of the copper foil current collector.

At present, the research on the recycling of wastelithium batteries is mainly focused on the recovery of high-value anode precious metals cobaltand lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is animportant production raw material widely used.Carbon powder adhered to it can be used asadditives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficientseparation and recovery of waste lithium batteries.

The pretreatment process of Lithium Batetry Recycling Plant mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

| Attributes |

Attribute Value |

| Recovery Rate of Metallic Aluminum |

>98% |

| Powder Recovery Rate |

>98% |

| Content of Powder In Metal Aluminum |

<2% |

| Content of Metallic Aluminum In Powder |

<2% |

| Qualified Rate |

99% |

| Failure Rate |

<1% |

| CMR |

≥1.67 |

| Applicable Industries |

Manufacturing Plant, Machinery Repair Shops, Construction works |

| Showroom Location |

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Russia, Thailand, Kenya, Argentina, South Korea, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan |

| Place of Origin |

Henan, China |

| Final product |

Copper, Aluminum, Paper, Cobalt Lithium & Graphite Mix Powder |

| Control |

PLC+PC+Touch Screen |

| Feature |

Easy Operation; High Seperation Rate |

.png) Product Description

Product Description Model Number: ZY-1500

Model Number: ZY-1500 Certification: CE

Certification: CE Warranty: 2 Year

Warranty: 2 Year Voltage: 220V/380V/Customized

Voltage: 220V/380V/Customized

Inquiry Form