Online WhatsApp:

+86-19903886476Online WhatsApp:

+86-19903886476

COMPANY PROFILE

SUNY GROUP

A company that specializes in designing and producingBattery Recycling equipment.

Suny Group continues to be driven by a clear vision of pursuing excellence in technology and engineering. Its uncompromising quality standards and persistent pursuit of continuous innovation have made it a leading global Lithium Battery Recycling equipment company in the international market.

Suny Group leverages its ability to integrate technology, processes and customer needs to skillfully deliver efficient solutions at very economical prices. Come to Suny Group to discover the latest Lithium Battery Recycling equipment.

Suny Group focuses on manufacturing and providing Battery Recycling equipment that meets international standards. With a history of more than 20 years, it is very popular in the European market because the equipment complies with CE certification standards and ensures operation under strict European quality requirements. Commitment to excellent after-sales service, including technical support, training services and equipment maintenance. Ensure customers achieve maximum efficiency and reliability when using equipment. Suny Group, your trusted partner, takes your business to new heights in the global market.

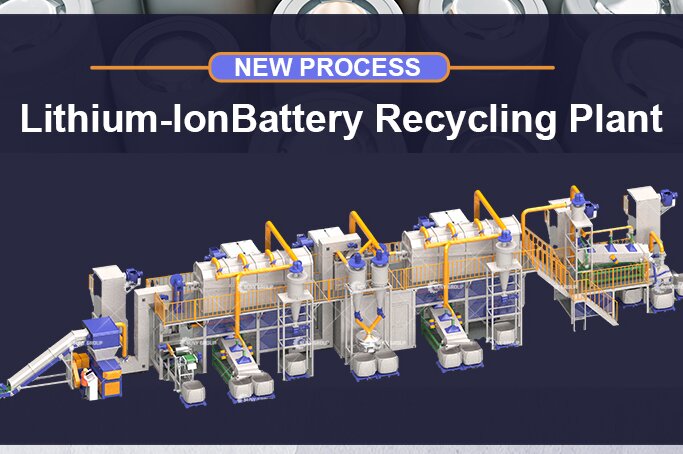

Lithium Battery Recycling Machine

SUNY GROUP

Our lithium-ion battery recycling line is designed for recycling and processing various types of waste lithium batteries, including mobile phone batteries, laptop batteries and electric vehicle batteries.

The system uses advanced crushing, sorting and gravity separation technology to efficiently recycle valuable metals such as aluminum, copper, plastic, steel shell and black powder, ensuring resource recycling and environmentally friendly treatment.

The whole set of units includes: shredder, hammer vibration crusher, belt conveyor, magnetic separator, fine crusher, belt conveyor, vibration grading screen, positive and negative electrode fine crusher, analyzer, collector, pulse dust collector, inert gas protection device, electrolyte volatile adsorption purification system, photo-oxygen low-temperature plasma purification equipment, electronic control system and connecting pipelines, etc.

The pretreatment process equipment can be divided into single cell crushing part and positive and negative electrode crushing part. The recycling equipment starts with manual sorting of waste batteries, and goes through battery pack disassembly, single cell discharge, crushing, magnetic separation, wind separation, vibration grading screening and other equipment.

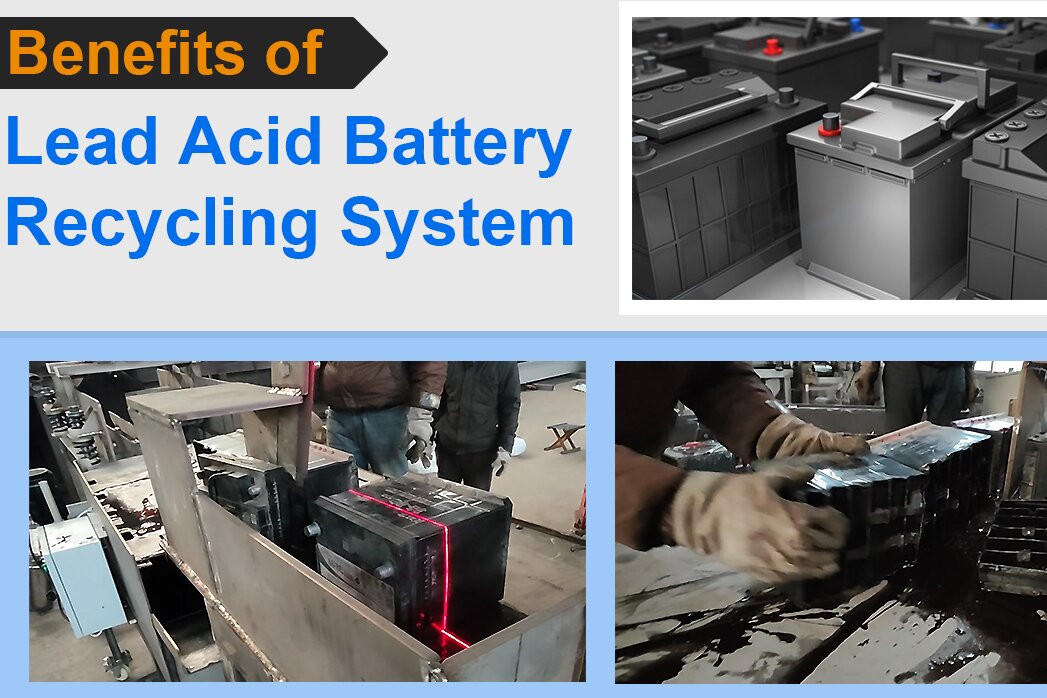

Lead-Acid Battery Recycling Machine

SUNY GROUP

The lead-acid battery recycling line is suitable for recycling various lead-acid batteries, such as car batteries, truck batteries, electric bicycle batteries, etc. First, the waste lead-acid batteries will be separated by a "battery separator". The final products of the separation section are plastics, lead, acid. Crude lead can be refined by the smelting department.

In the recycling process, we need to obtain plastic casing, electrolyte, lead (lead plates and lead grids) and some metals such as copper and iron from used lead-acid batteries. To obtain these usable and valuable materials, the old technical solution is to rely on manual labor. Mechanical cutting or manual disassembly is usually used. Care is required during disassembly to prevent electrolyte leakage. After disassembly, the different components inside the battery are separated, including lead plates, lead grids, plastic casing and electrolyte. Manual disassembly and recycling solutions are too inefficient, too costly and dangerous. Our technicians have designed and manufactured automated machines to recycle lead-acid batteries through technological research and development.

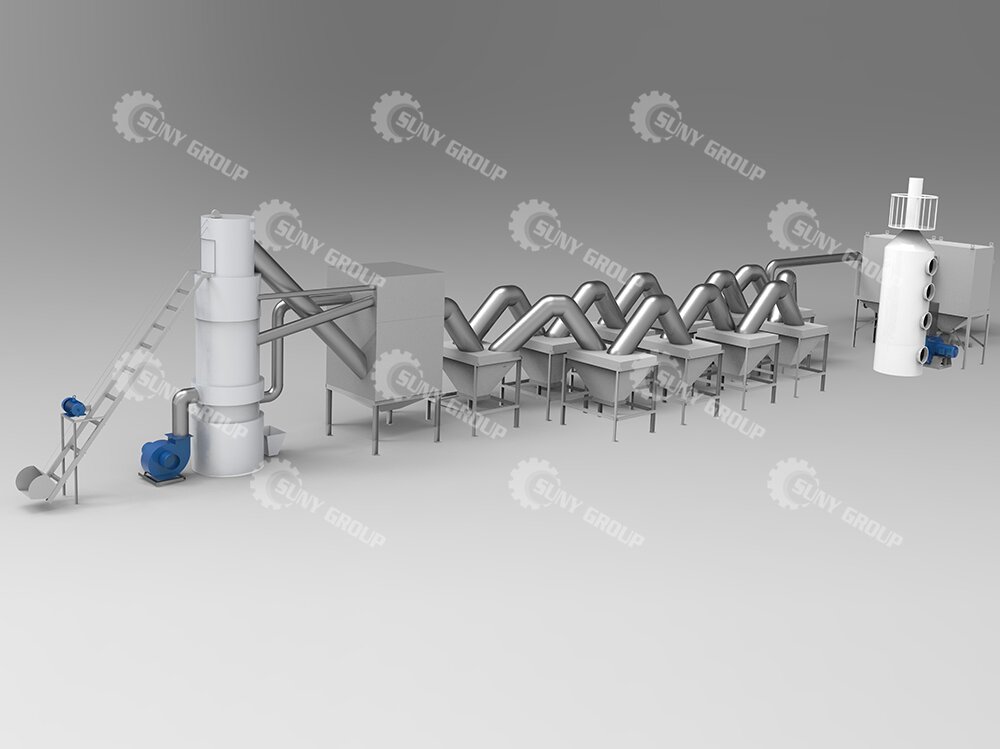

Continuous Smelting Furnace

SUNY GROUP

The entire production line of the lead ingot smelting cup furnace for recycling used automotive batteries focuses on environmental protection. First, the used lead-acid batteries will be separated by a “battery separator”, and the separated final products include plastics, lead, and acid. The crude lead can be refined through the smelting section, and if deep recycling is required, a cup furnace can be selected to obtain refined lead ingots. The smelting section is also equipped with an air pollution purification system to meet the requirements of environmental protection policies.

The whole line of Scrap Battery Recycle Cupola Furnace For Lead Melting is environmental protection. Firstly the scrap lead acid battery will be separated by the “Battery Separating machine”. The final produts of separation section is plastic, lead, acid. The coarse lead can be refined by Smelting Section. And then you can choose the Cupola Furnace to get the refined lead ingot if you want to get deeply recycle. As for the Smelting Section, there is also Air Pollution Purify System to meet the environmental protection policy.

There is the environmental protection system installed combined with the cupola furnace, which can keep there is an efficient pollution control system in steady. The composition of waste gas contains: CO2, CO, SO2 and dust.

Inquiry Form